Tue, May 27, 2014

Temperature Range And Vacuum Of Space Simulated In Most Recent Tests

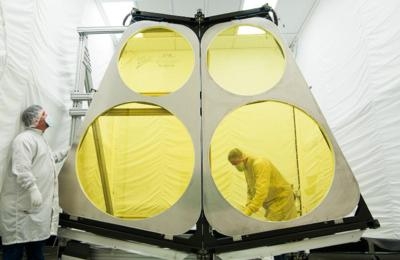

Thermal vacuum environmental tests on critical components for the Defense Advanced Research Projects Agency (DARPA) Membrane Optic Imager Real-Time Exploitation (MOIRE) telescope has been completed by Ball Aerospace. Two sections of the primary mirror composite back structure and the structure deployment hinges successfully underwent environmental tests to simulate the temperature range and vacuum of a space environment.

"Results from the environmental tests are very promising for future application of the technology," said David Kaufman, vice president & general manager for Ball's National Defense strategic business unit. "By retiring risk and increasing TRL (technology readiness level) of key components we are one step closer to providing persistent imaging from space that many communities are eager to access."

Image quality from space is dependent on a stable platform. The composite back structure developed by ATK Space Components provides a lightweight option with the required stability needed for persistent imaging from geostationary orbit. Ball Aerospace designed and built the deployment hinges that would be used to unfold the telescope primary in space. Testing the hinges in a relevant environment helps retire risk and proves the required stability characteristics of the primary.

The DARPA MOIRE program is demonstrating the ability to decrease mass and costs of large imaging systems using lightweight diffractive membrane optics. Since the contract award in 2010, Ball Aerospace has been incrementally maturing the manufacturability required for large collection area telescopes (up to 20 meters). The subassemblies used in the most recent test are needed to hold the membrane optics tight and flat, and provide the necessary image quality of the system. Environmental testing of the components is the final phase of DARPA funding for the MOIRE program. "As a company with a rich heritage in space optics, this is both an innovative program for Ball Aerospace and a paradigm shift," added Kaufman. "By using replicated optics techniques to deliver affordability there is no longer a lengthy manufacturing process of glass mirrors, but instead a process similar to a printing press."

(Image provided by Ball Aerospace)

More News

Pilot Applied Full Aft Stick And Nose-Up Trim, But The Airplane Remained On The Runway Analysis: The pilot reported that a preflight inspection and flight control checks revealed n>[...]

A Few Questions AND Answers To Help You Get MORE Out of ANN! 1) I forgot my password. How do I find it? 1) Easy... click here and give us your e-mail address--we'll send it to you >[...]

From 2022 (YouTube Edition): Before They’re All Gone... Humankind has been messing about in airplanes for almost 120-years. In that time, thousands of aircraft representing i>[...]

Advanced Air Mobility (AAM) A transportation system that transports people and property by air between two points in the NAS using aircraft with advanced technologies, including el>[...]

Aero Linx: MQ-1B Predator The MQ-1B Predator is an armed, multi-mission, medium-altitude, long-endurance remotely piloted aircraft that is employed primarily as an intelligence-col>[...]

NTSB Final Report: Douglas A-4K

NTSB Final Report: Douglas A-4K ANN FAQ: Q&A 101

ANN FAQ: Q&A 101 Classic Aero-TV: PBY Catalina--From Wartime to Double Sunrise to the Long Sunset

Classic Aero-TV: PBY Catalina--From Wartime to Double Sunrise to the Long Sunset ANN's Daily Aero-Term (07.01.25): Advanced Air Mobility (AAM)

ANN's Daily Aero-Term (07.01.25): Advanced Air Mobility (AAM) ANN's Daily Aero-Linx (07.01.25)

ANN's Daily Aero-Linx (07.01.25)