The Air Force Is Analyzing Operational Efficiency – One Airframe At A Time

Aerodynamics testing on the KC-135 Stratotanker confirmed vertically mounted wiper blades reduce aircraft drag by approximately 1% during cruise conditions, potentially saving the Air Force $7 million annually in associated fuel costs.

Across the KC-135 fleet, blades are positioned horizontally on the windshield as part of the aircraft’s original 1950s design. However, as the understanding of aviation aerodynamics advanced, research indicated placing the wipers vertically when not in use could improve aerodynamic efficiency and optimize fuel use.

Commercial airliners first demonstrated the concept on the McDonnell Douglas MD-11, a jet airliner primarily used by the cargo industry, proving that retro-fitting the blades vertically could decrease costly drag by 1.2%.

As part of the effort to increase the capability of legacy aircraft, the Advanced Power and Technology Office, or APTO, part of the Air Force Research Laboratory, identified the KC-135 as a candidate for the modification in 2019, citing its horizontal wiper design and significant fuel use.

According to 2019 data from the Air Force Total Ownership Cost database, the KC-135 fleet consumed over 260 million gallons last year, accounting for almost 14% of total Air Force aviation fuel use.

“We’re partnering with the Southwest Research Institute, the Air National Guard and the Air Force Operational Energy office to validate the concept and determine actual efficiency gains,” said Ed Clark, APTO aviation program lead overseeing the initiative.

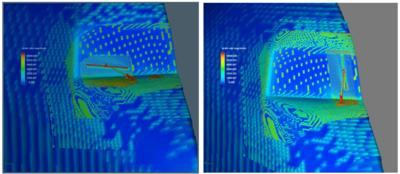

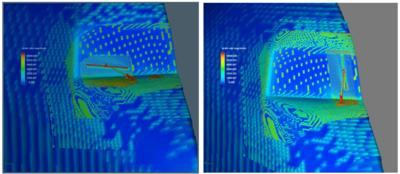

The team of researchers and aeronautical engineers employed a KC-135 from Rickenbacker Air National Guard Base in Ohio for comprehensive ground testing on the airframe. Using computational fluid dynamics, or CFD, they were able to model how air flows over the nose and windshield of the aircraft during flight, simulating both vertical and horizontal wiper positions.

The CFD models enabled the Rickenbacker team to visualize areas on the airframe that produce higher drag, (shown in red in the photo posted along with this story) and identify potential efficiencies. According to the report, data showed a reduction in drag of 0.8% for re-positioning the blade vertically, and 0.2% for the slimmer wiper design.

“This is a significant milestone for us. Over several months, we performed thousands of flight configurations during CFD testing to prove efficiency gains on the KC-135,” Clark remarked. “Now, we’re ready to move on to airworthiness testing and certify its use with the (Federal Aviation Administration).”

The team plans to further refine the wiper design and layout over the coming months, with the next phase scheduled for summer 2020. They have also partnered with Delta Airlines, which plans to leverage some of the lessons learned on the KC-135 effort to assess the potential of utilizing vertical wipers on their Boeing 767 fleet.

“While 1% efficiency may not seem like a lot, it equates to millions of dollars in fuel savings each year, which can then be re-invested into other programs,” explained Daniel Pike, acquisition manager and chief of future operations for Air Force Operational Energy, whose office is helping to fund the initiative. “When you combine the results of optimization efforts across multiple aircraft, you start to understand how much of an impact this could have.”

As the Air Force seeks to improve the range and capability of its legacy aircraft, researchers and subject matter experts from APTO and the Operational Energy office are exploring several ways to increase efficiency through optimized operations, modern technology and drag reduction initiatives.

ANN's Daily Aero-Linx (05.06.25)

ANN's Daily Aero-Linx (05.06.25) ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF)

ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF) ANN FAQ: Q&A 101

ANN FAQ: Q&A 101 Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training

Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance

Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance