Wed, Oct 12, 2022

T901 Shaping Up to Offer 50% Power Bump with 25% Better Fuel Burn

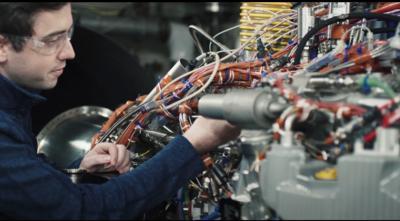

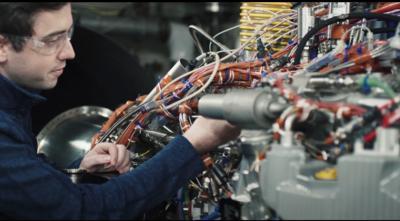

GE Aerospace is on track for next year's T-901 testing program, getting ready to put the next-generation rotorcraft engine through its paces for installation in a range of combat helicopters.

The T901-GE-900 will ultimately power the US Army's UH-60 Black Hawk, the AH-64 Apache, and the upcoming Future Attack Reconnaissance Aircraft (FARA) once ready for duty. The testing process is part of the Engineering and Manufacturing Development (EMD) phase of the Army’s Improved Turbine Engine (ITE) program. Once complete, the program is expected to offer a substantive leap in reliability and performance, boosting performance and minimizing downtime for combat aircraft.

Key to the improvements over legacy engine systems is the simplification of parts made possible through modern additive manufacturing. The rapid advancement of industrial scale 3d printing allows considerable reductions in machining and forging smaller parts, reducing failure points and combining processes for greater resiliency throughout the life of the unit. Combined with a series of modern materials, the resulting engine is proving to be an impressive upgrade over the Army's current helicopter workhorse, the GE T700. The T901 provides 50% more power over its older counterpart, putting out 3,000 shaft horsepower. Army personnel undoubtedly eye the program with excitement at the prospect of once again having their aircraft's full payload capacity even in hot and high climates. Like any modern upgrade, the performance boost comes alongside improvements in fuel consumption, with the T901 boasting 25% greater fuel economy in flight.

“Testing of the first T901 engine was very successful with the engine accumulating more than 100 hours of run time,” said Tom Champion, GE’s T901 Program Director. “We were impressed with the performance and condition of the engine’s compressor, combustor, and turbine sections as well as the 3D-printed (additive) manufactured parts and ceramic matrix composite (CMC) components.”

Under the program, 8 initial T901 engines will be built as a part of the Army's airworthiness certification program, ultimately logging thousands of hours and testing on each before giving them the go-ahead for combat use. So far, the first T901 unit has been put through 1,500 hours of full-scale ground testing for its preliminary flight rating, with nearly 5,000 hours of engine qualification testing, with many more well on the way.

More News

Aero Linx: International Federation of Airworthiness (IFA) We aim to be the most internationally respected independent authority on the subject of Airworthiness. IFA uniquely combi>[...]

Ultrahigh Frequency (UHF) The frequency band between 300 and 3,000 MHz. The bank of radio frequencies used for military air/ground voice communications. In some instances this may >[...]

A Few Questions AND Answers To Help You Get MORE Out of ANN! 1) I forgot my password. How do I find it? 1) Easy... click here and give us your e-mail address--we'll send it to you >[...]

From 2019 (YouTube Edition): Learning To Paint Without Getting Any On Your Hands PPG's Aerospace Coatings Academy is a tool designed to teach everything one needs to know about all>[...]

Also: Sustainable Aircraft Test Put Aside, More Falcon 9 Ops, Wyoming ANG Rescue, Oreo Cookie Into Orbit Joby Aviation has reason to celebrate, recently completing its first full t>[...]

ANN's Daily Aero-Linx (05.06.25)

ANN's Daily Aero-Linx (05.06.25) ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF)

ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF) ANN FAQ: Q&A 101

ANN FAQ: Q&A 101 Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training

Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance

Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance