Emergence of a Benchmark

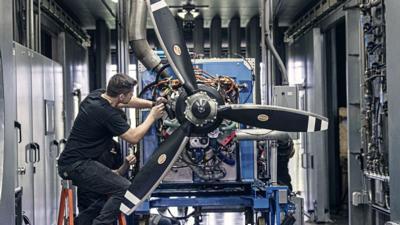

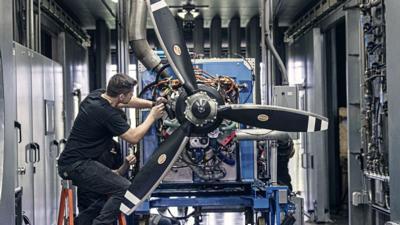

Racine, Wisconsin-based DeltaHawk is a privately-held manufacturer of reciprocating engines for aircraft and hybrid power systems. The company and its teams of engineers, designers, manufacturing specialists, flight test, and certification experts is about the business of building a new generation of patented, FAA-certified, jet-fuel-burning, aviation piston engines for a wide variety of general aviation, military, and experimental aircraft and ground-based applications.

In May 2023, DeltaHawk’s DHK180 powerplant was granted FAA Type Certification. Comes now July 2023 and DeltaHawk’s announcement that the company is accepting reservation deposits for its DHK180 piston aero-engine, with initial deliveries slated to commence in the first half of 2024.

The jet fuel burning, 180-horsepower DHK180 is the first of a planned family of DeltaHawk engines and offers ease of operation, high fuel efficiency, reduced maintenance, and superior altitude performance compared to traditional aircraft piston engines. The company has received vigorous interest in the new engine from a broad range of aircraft OEMs and experimental kit manufacturers, as well as individual pilots and commercial operators.

In addition to having been chosen by NASA for the agency’s Subsonic Single Aft Engine Project (SUSAN), DeltaHawk’s DHK180 engine was selected by Ampaire to power, in part, a hybrid proof-of-concept aircraft. (Yup... they're BUSY...)

In preparation for production and commercial sales, DeltaHawk is performing additional endurance testing and flight evaluations of its DHK180 engine in numerous aircraft. The imminence of full-scale manufacturing is evinced by the entrance of the powerplant’s constituent parts into the global supply-chain.

DeltaHawk’s newly-announced factory warranty program covers the DHK180 engine for 24 months or two-thousand hours, whichever comes first. Operators agreeing to provide timely engine-monitoring data and oil analysis may have their warranties extended to 36 months or 2,400 hours—an industry-leading option.

Deliveries of DeltaHawk’s DHK180 engine for both certified and experimental aircraft will include firewall-forward installation packages for specific aircraft. Packages for selected aircraft are currently under development. Final pricing for such will be announced presently.

To augment its capabilities, DeltaHawk is actively seeking industry partners with engine installation STC experience.

Field service for DeltaHawk’s new DHK180 engine will be available through a planned network of qualified service providers, which the company is actively recruiting. All factory authorized DeltaHawk service facilities will be supported by the company’s in-house experts, as well extensive on-line training programs.

Owing to the engine’s clean-sheet design, development and certification of DeltaHawk’s DHK180 was at once time-consuming and costly. It is widely hoped, however, that the significant time and kingly monies invested in the powerplant’s engineering and production will see the DHK180 emerge as the benchmark against which the entirety of general aviation reciprocating engines will henceforth be measured.

NTSB Prelim: Hy-Tek Hurricane HP

NTSB Prelim: Hy-Tek Hurricane HP ANN's Daily Aero-Term (05.14.25): Flight Check

ANN's Daily Aero-Term (05.14.25): Flight Check Aero-News: Quote of the Day (05.14.25)

Aero-News: Quote of the Day (05.14.25) ANN's Daily Aero-Term (05.15.25): Primary Radar

ANN's Daily Aero-Term (05.15.25): Primary Radar Airborne 05.12.25: $1M Flying Car, Marion Airport Saved, AirVenture Cup

Airborne 05.12.25: $1M Flying Car, Marion Airport Saved, AirVenture Cup