Back After 28 Years of Would, Could, and Should Haves

Special 04.01.23 Parody Edition: The relatively short-lived confluence of the Beechcraft and Hawker marques under the Raytheon banner has—a full decade after its 2013 bankruptcy—yielded strange fruit.

On 01 April 2023, Beechcraft—now a subsidiary of Textron Aviation—announced prototyping of an updated iteration of the company’s iconic, if not altogether successful, Starship business aircraft would commence in early 2024.

The decision to resurrect Beechcraft’s startlingly-gorgeous, famously-flopped, twin-turboprop—which will ostensibly compete directly with the company’s highly-successful King-Air family of aircraft—derives primarily of vast improvements in the processes by which composite aircraft structures and components are manufactured.

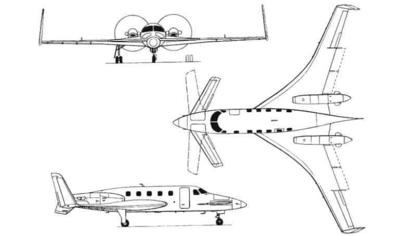

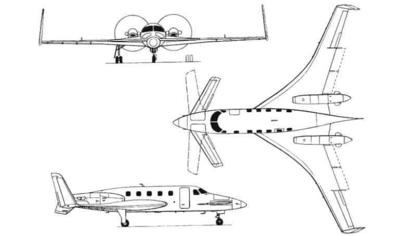

Green-lit in 1979, the original Starship was noteworthy for its carbon fiber composite airframe, canard design, lack of a conventional, centrally-located vertical-stabilizer/rudder assembly, and aft-facing engine/pusher-propeller configuration. The model was envisaged as a sleeker, swifter, more stylish successor to the aforementioned King Air line of turboprops.

Killing the King Air, however, proved more difficult than Beechcraft’s brass imagined.

Originated in January 1980 as Preliminary Design 330 (PD-330), the Starship project was joined in 1982 by Burt Rutan’s Scaled Composites—an American aerospace design firm renowned for its unconventional designs and use of non-metal, composite materials.

Among the significant changes made by Scaled Composites to Beechcraft’s original PD-330 design was the addition of variable geometry to the aircraft’s forward canard.

Prototypes of the inchoate Starship design were produced even as development work moved forward—a system necessitated by the then-primitive, inefficient, and inordinately costly state of composite technologies and manufacturing processes.

Beech built three airworthy full-scale prototypes: NC-1, which was used for aerodynamic testing, sported an ejection seat, and was the one and only Starship equipped with conventional electro-mechanical avionics; NC-2, which was used for avionics and systems testing; and NC-3, which was used for flight management system and powerplant testing. NC-1 made its maiden flight on 15 February 1986.

Regrettably, the Starship program was repeatedly delayed. Initial setbacks were attributable to Beechcraft engineers’ underestimation of the model’s developmental complexity and the steep learning curve inherent the manufacturing and layup of its composite fuselage and main wing. Subsequent delays derived of technical difficulties arising from the correction of a pitch-damping anomaly and the development of the aircraft’s stall-warning system. By the end of its evolution, the Starship’s was worryingly less and worryingly more than the revolutionary aircraft Beechcraft had set out to create.

Following a $300-million evolution (2023 equivalent $727,838,710), the first production Starship flew on 25 April 1989.

In the late 1980s, carbon-fiber composites were used to varying degrees in the construction of military aircraft. The Starship, however, was the first civilian airplane to make extensive use of such materials. Beechcraft predicated its decision to build the Starship primarily from carbon fiber composites upon the stuff’s superb durability and favorable strength-to-weight ratio. The Starship was to weigh less than a conventional aluminum airplane of its dimensions. Alas, the empty weight of production specimens exceeded design targets—and more catastrophically, marketing claims—by several thousand pounds.

The Starship’s standard flight instrumentation was as unconventional as the machine itself, and included a Rockwell Collins supplied Proline 4 AMS-850 glass cockpit sporting a whopping 14 Cathode Ray Tube (CRT) displays. EFIS was exceedingly rare in the 1980s, appearing solely in the newest airliners and military aircraft. That a 14-tube EFIS system—despite being the first such suite offered in a business aircraft—added to the Starship’s portliness is retrospectively counted among the design’s major flaws.

Beechcraft sold only eleven Starships in the three years following the model’s type certification. The company attributed the slow sales to the economic downturn of the late-1980s, the novelty of the Starship, and the tax on luxury items peculiar to George H. W. Bush‘s United States.

Viewed through history’s decidedly clearer lens, the Starship’s commercial failure was occasioned by a lethal combination of high-price and poor performance.

In 1989, the Starship’s list price was a kingly $3.9-million—about the same as Cessna’s Citation V and LearJet’s superb 31-model—aircraft with maximum cruise speeds respectively 89 and 124-knots faster than that of the Starship. Also speedier than the Starship, Piper’s Cheyanne twin-turboprop retailed for a full $1-million less than Beechcraft’s unorthodox offering.

Comes now 2023 and a global aircraft market replete with composite fuselages, empennages, flight-controls, and even wings. Carbon-fiber layup work that, in the early 1990s, demanded hundreds of man hours and resulted in waste-ratios as high as thirty-percent, is now completed by a single robotic machine in a fraction of the time at a fraction of the cost and with near-zero waste.

Beechcraft has fortified its production facilities with the full complement of 21st Century technologies prerequisite the Starship’s second coming. What’s more, institutional knowledge gleaned during the company’s 2001–2012 dalliance with the Premier I and II light-jets promises to correlate directly to renewed Starship production.

Speaking at a 01 April press conference in Wichita, Kansas, Textron Aviation CEO Ronald Draper described the new aircraft—which on account of SpaceX’s ownership of the Starship moniker is to be dubbed the Model 2100 Tangy Bonanza—as “the actualization of concept with which the world has finally caught up.”

“It’s an airplane that defies time and captivates imagination,” Mr. Draper declared. “Today’s digital and material technologies will finally allow Beechcraft engineers to bring to market the airplane their predecessors and Burt Rutan had in mind in the early 1980s.”

In his overview of the Model 2100, Textron Aviation Senior Engineering Manager Jeff Johannsmeyer presented a larger, slipperier, faster, more powerful, aircraft than the original Model 2000 Starship. The Tangy Bonanza is slated to measure 55-feet, 9-inches from radome to aft body-strake—nearly ten-feet longer than its forebear, and accommodate two in the cockpit and ten in the cabin. The new aircraft’s jet-like swept wings span 72-feet, 7-inches and retain the Model 2000’s tipsails—massively oversized blended-winglets augmented with trailing-edge rudder assemblies.

The Model 2100 Tangy Bonanza improves on the Model 2000’s 1,200-shaft-horsepower Pratt & Whitney PT6A-67A turboprop engines with a pair of 1,600-shaft-horsepower PT6A-68T mills mated to Raisbeck/Hartzell, structural-composite, five-scimitar-blade, constant-speed, full-feathering, reversible, pusher-propellers. Modern efficiency aside, the new engines’ additional horsepower raises a thirst that makes good use of the Tangy Bonanza’s eight-hundred-gallon (5,440-pound) usable fuel capacity. Topped up with Jet-A and laden with six passengers and their baggage, the Model 2100 manages a 2,900-nautical-mile range at its FL350 service-ceiling.

The Tangy Bonanza’s speed envelope is bordered by a 412-knot Vne and a 97-knot Vso stall-speed. Interposed between is a fleet high-speed cruise of 380-knots. By virtue of its variable incidence canard, the Tangy Bonanza is difficult to stall. Even power-on stalls are aerodynamically evinced by only a gentle buffeting. Persistent control-yoke back-pressure precipitates a predictable, straight-ahead drop of the aircraft’s nose. Because the canard stalls prior to the main wing, aileron control remains constant and authoritative throughout the stall and recovery.

After the fashion of its King Air cousins, the Tangy Bonanza is a single-pilot ship. However, owing to its 19,000-pound maximum takeoff weight, pilots aspiring to fly the machine will be obligated to call upon FlightSafety International’s Wichita East Learning Center for purpose of securing for themselves a Model 2100 type-rating.

Once appropriately schooled and type-rated, Tangy Bonanza pilots will enjoy availing themselves of the Collins Aerospace Pro-Line Fusion avionics suite. Adaptive, intuitive, and fully integrated, the Pro-Line architecture features touch-control Primary Flight Displays (PFD); intuitive graphical touch-screen flight planning; a high-resolution Synthetic Vision System (SVS) with patented airport graphics; convenient presets to reconfigure all three displays with a single touch; a full multi-sensor flight management system; integrated touch-screen checklists; and automatic wireless database and chart uploads.

The Model 2100’s Pro-Line suite, by dint of its open design and scalability, is eminently capable of accommodating future upgrades and regulatory mandates. Additionally, the Pro-Line system includes NextGen and precision GPS capabilities the likes of: DO-260B compliant ADS-B, SBAS-capable GNSS, localizer performance with vertical guidance (LPV) approaches, radius-to-fix (RF) legs, and numerous additional bits of digital wizardry.

The Model 2100’s modernized center pedestal affords pilots the flexibility of multiple input methods, thereby facilitating heads-up flying and greater ease of use.

Following development, prototyping, and flight-testing, the Model 2100 Tangy Bonanza will be produced at Beechcraft’s Wichita, Kansas plant. Current estimates put first flight in late-2025, FAA type certification in mid-2026, and first deliveries in 2026’s fourth quarter. The aircraft will be offered in only a premium trim-level with a projected turn-key price of $12-million.

Airborne-Flight Training 05.09.24: ERAU at AIAA, LIFT Diamond Buy, Epic A&P

Airborne-Flight Training 05.09.24: ERAU at AIAA, LIFT Diamond Buy, Epic A&P ANN's Daily Aero-Term (05.07.24): Hazardous Weather Information

ANN's Daily Aero-Term (05.07.24): Hazardous Weather Information Aero-News: Quote of the Day (05.07.24)

Aero-News: Quote of the Day (05.07.24) NTSB Final Report: Cessna 150

NTSB Final Report: Cessna 150 Aero-News: Quote of the Day (05.08.24)

Aero-News: Quote of the Day (05.08.24)