Procedures Needed To Prevent Power Loss During Takeoff, Climb

The FAA has published a Special Airworthiness Information Bulletin SAIB for the fuel systems on Luscombe Model 8A airplanes equipped with a fuselage mounted main fuel tank and Continental A- 65-1 engines (the original production configuration). The SAIB addresses the need for procedures to prevent the possible loss of power on takeoff and climb.

Since certification in 1939, there have been reports of power loss on Luscombe Model 8A airplanes. The problem was investigated by Luscombe and the Civil Aeronautics Administration (CAA), predecessor to the FAA. Flight testing revealed that fuel flow could be interrupted from the fuselage mounted tank as a result of acceleration and higher pitch attitudes commonly encountered in takeoff and climb.

Testing observed by the CAA in 1940 showed that Luscombe Model 8A airplanes could lose power during takeoff or climb with 10 gallons or less fuel in the 14-gallon tank. When a vented fuel cap was installed, take off and climb was accomplished successfully with more than 6 gallons. Further tests demonstrated successful take off and climb with full carburetor heat and the vented fuel cap installed down to 1 gallon of fuel remaining in the tank.

The vented fuel cap (shown below) and use of carburetor heat on takeoff work together to prevent interruption of fuel flow to the engine. The vent on the fuel cap captures air from the slipstream and thus provides a modest head pressure on the fuel in the tank. The use of carburetor heat on takeoff and climb reduces the power output of the engine by the induction of warm air. As a result, the pitch attitude of the airplane decreases. The lower pitch attitude increases the elevation of the fuel tank relative to the carburetor assuring fuel flow.

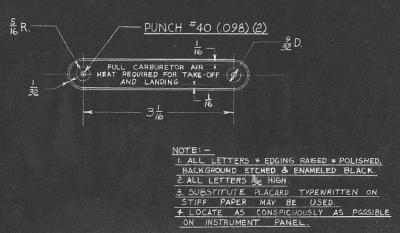

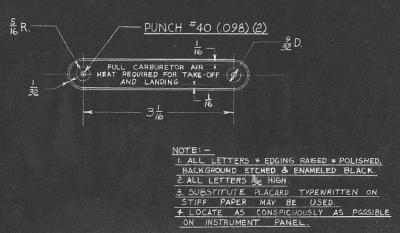

The CAA issued Airworthiness Maintenance Bulletin No. 40 February 25, 1941, specifying the installation of a vented fuel cap and a placard revising carburetor heat usage. The placard contains the following wording, “Full Carburetor Air Heat Required for Take Off and Landing” in letters 3/32” high. The placard was fabricated from .032” thick aluminum (pictured here).

Bulletin No. 40 also recommended installation of Luscombe Part No. 486021, Fuel Cap-Pressure Vent. Subsequently, other cap designs were approved by the manufacturer. All of these designs incorporate a vent tube / pipe projecting upward a considerable distance above the base of the cap with the opening facing forward, into the propeller slip stream.

A later design fuel cap utilizes a rigid steel 3/8” diameter tube section extending about 8” above the cap with a 1.25” radius bend forward into the airstream. These caps have a marking at the base with an arrow and black letters “FORWARD.” The information in Bulletin No. 40 was subsequently placed in Aircraft Specification No. A-694 Note 2.

The Luscombe 8A has unique procedures. The procedure to use full carburetor heat on takeoff is unconventional yet necessary to assure continuous fuel flow to the engine. Also, the vented fuel cap must be installed with the vent opening facing forward into the prevailing air stream. It is physically possible to install the fuel cap backwards; this condition will decrease fuel flow from the tank. The cap should have lettering indicating the forward direction. If the “Forward“ lettering is missing or obscured it should be renewed. During pre-flight inspection, while the cap is removed, it is advisable to check the vent function by blowing into the vent tube.

(Luscombe 8A pictured in file photo. Others provided by the FAA)

ANN's Daily Aero-Term (04.24.24): Runway Lead-in Light System

ANN's Daily Aero-Term (04.24.24): Runway Lead-in Light System ANN's Daily Aero-Linx (04.24.24)

ANN's Daily Aero-Linx (04.24.24) Aero-FAQ: Dave Juwel's Aviation Marketing Stories -- ITBOA BNITBOB

Aero-FAQ: Dave Juwel's Aviation Marketing Stories -- ITBOA BNITBOB Classic Aero-TV: Best Seat in The House -- 'Inside' The AeroShell Aerobatic Team

Classic Aero-TV: Best Seat in The House -- 'Inside' The AeroShell Aerobatic Team Airborne Affordable Flyers 04.18.24: CarbonCub UL, Fisher, Affordable Flyer Expo

Airborne Affordable Flyers 04.18.24: CarbonCub UL, Fisher, Affordable Flyer Expo