Tue, Jul 20, 2004

New Generation High Performance Resin For Aerospace And

Commercial Applications

UBE America and NASA have entered

into a license agreement for NASA's PETI-330. The announcement was

made by representatives of NASA, UBE America and UBE Industries

during the recent SAMPE meeting in Long Beach (CA).

UBE America and NASA have entered

into a license agreement for NASA's PETI-330. The announcement was

made by representatives of NASA, UBE America and UBE Industries

during the recent SAMPE meeting in Long Beach (CA).

PETI-330 was developed at NASA-Langley by a team headed by John

W. Connell and is covered by US Patent No. 6,359,107, "Composition

of and method for making high performance resins for infusion and

transfer molding processes." PETI-330 offers cost effective and

affordable fabrication of high temperature composite structures for

advanced aerospace vehicles. The unique combination of high

temperature performance and processing characteristics enables new

applications.

PETI-330 will be marketed and sold in North America by UBE

America under the license from NASA.

PETI-330 offers the following innovative characteristics:

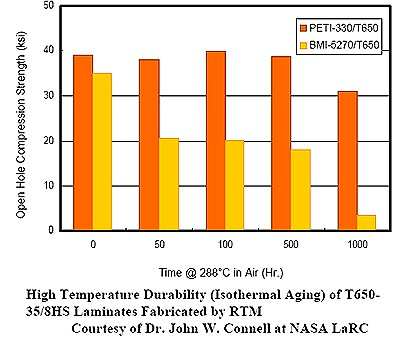

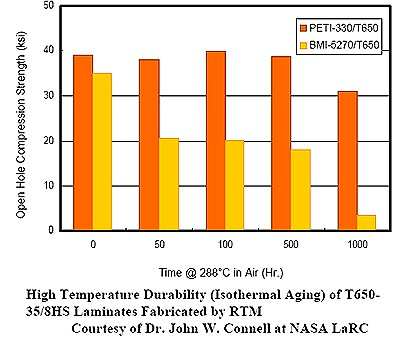

- PETI-330 composites have excellent long-term (1,000 hours)

performance at 300�C.

PETI-330 provides an unprecedented combination of easy processing

for composite fabrication together with high temperature

performance and toughness.

- PETI-330 offers low (<10 Pa-s, 288�C) and stable melt

viscosity highly suited to RTM and other resin infusion

processes.

- There is a simple and efficient 1-hour full cure process with

no post-cure required.

- It has a high glass transition temperature 330�C /

626�F

- PETI-330 is both solvent free (no volatiles) and non toxic

- These characteristics provide the following benefits:

- Substantial improvements in both high and low temperature

performance compared with traditional materials such as epoxies or

bismaleimides.

- Superior combination of processability and mechanical

properties compared with existing polyimides such as PMR-15

- A simplified cure process which makes it highly suitable for

mass production requirements

- A reduced fabrication time for components and assemblies

- Reduced mass & weight for high temperature structural

applications (i.e. it can replace metallic parts and

assemblies)

- A more cost effective alternative to complex part

assembly

A spokesman for UBE stated, "UBE Industries will fully support

the efforts of UBE America to develop and expand the market for

this revolutionary resin. UBE continues its research and

development work on new resins for aerospace applications."

"The first market to benefit from this new technology will be

the aerospace industry, particularly the military sector. PETI-330

will replace metal parts of the aircraft, including helicopters,

which will considerably decrease their weight," said Kei Tsukahara,

product manager, UBE America.

"We expect a great demand for this exciting new product. UBE

America is currently working on creating an inventory of samples

for potential customers," said Tsukahara.

UBE Industries has a patent on additional types of polyimide

using a-BPDA in the United States. It is currently filing for

patents in Europe and Japan.

PETI-330 complements the existing portfolio of products offered by

UBE for the aerospace industry, including UPILEX Polyimide Film and

TYRANNO Silicon Carbide Fiber.

More News

Aero Linx: International Federation of Airworthiness (IFA) We aim to be the most internationally respected independent authority on the subject of Airworthiness. IFA uniquely combi>[...]

Ultrahigh Frequency (UHF) The frequency band between 300 and 3,000 MHz. The bank of radio frequencies used for military air/ground voice communications. In some instances this may >[...]

A Few Questions AND Answers To Help You Get MORE Out of ANN! 1) I forgot my password. How do I find it? 1) Easy... click here and give us your e-mail address--we'll send it to you >[...]

From 2019 (YouTube Edition): Learning To Paint Without Getting Any On Your Hands PPG's Aerospace Coatings Academy is a tool designed to teach everything one needs to know about all>[...]

Also: Sustainable Aircraft Test Put Aside, More Falcon 9 Ops, Wyoming ANG Rescue, Oreo Cookie Into Orbit Joby Aviation has reason to celebrate, recently completing its first full t>[...]

ANN's Daily Aero-Linx (05.06.25)

ANN's Daily Aero-Linx (05.06.25) ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF)

ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF) ANN FAQ: Q&A 101

ANN FAQ: Q&A 101 Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training

Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance

Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance