What They Had Was '...a Failure to Lubricate'

There are a lot of lessons here -- some about

flying, but particularly about maintenance.

There are a lot of lessons here -- some about

flying, but particularly about maintenance.

Everything is important; a little mistake can have great

consequences; cleanliness and lubrication are critical;

properly-designed tooling can make the difference; scientific

testing needs to precede changes in maintenance procedures; the

acceptable application of two different lubricants does not

necessarily mean the two lubes are compatible with each other;

and when you're in an emergency flight mode and find some

tactic that works, stick with it.

Here's what happened, straight from the NTSB:

1. The flight crewmembers on Alaska Airlines flight 261 were

properly certificated and qualified and had received the training

and off-duty time prescribed by Federal regulations. No evidence

indicated any preexisting medical or other condition that might

have adversely affected the flight crew's performance during the

accident flight.

2. The airplane was dispatched in accordance with Federal

Aviation Administration regulations and approved Alaska Airlines

procedures. The weight and balance of the airplane were within

limits for dispatch, takeoff, climb, and cruise.

3. Weather was not a factor in the accident.

4. There was no evidence of a fire or of impact with birds or

any other foreign object.

5. No evidence indicated that the airplane experienced any

preimpact structural or system failures, other than those

associated with the longitudinal trim control system, the

horizontal stabilizer, and its surrounding structure.

6. Both engines were operating normally before the final

dive.

7. Air traffic control personnel involved with the accident

flight were properly certificated and qualified for their assigned

duty stations.

8. The longitudinal trim control system on the accident airplane

was functioning normally during the initial phase of the accident

flight.

9. The horizontal stabilizer stopped responding to

autopilot and pilot commands after the airplane passed through

23,400 feet. The pilots recognized that the longitudinal trim

control system was jammed, but neither they nor the Alaska Airlines

maintenance personnel could determine the cause of the jam.

9. The horizontal stabilizer stopped responding to

autopilot and pilot commands after the airplane passed through

23,400 feet. The pilots recognized that the longitudinal trim

control system was jammed, but neither they nor the Alaska Airlines

maintenance personnel could determine the cause of the jam.

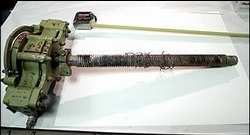

10. The worn threads inside the horizontal stabilizer acme nut

were incrementally sheared off by the acme screw and were

completely sheared off during the accident flight. As the airplane

passed through 23,400 feet, the acme screw and nut jammed,

preventing further movement of the horizontal stabilizer until the

initial dive.

11. The accident airplane's initial dive from 31,050 feet began

when the jam between the acme screw and nut was overcome as a

result of operation of the primary trim motor. Release of the jam

allowed the acme screw to pull up through the acme nut, causing the

horizontal stabilizer leading edge to move upward, thus causing the

airplane to pitch rapidly downward.

12. The acme screw did not completely separate from the acme nut

during the initial dive because the screw's lower mechanical stop

was restrained by the lower surface of the acme nut until just

before the second and final dive about 10 minutes later.

13. The cause of the final dive was the low-cycle fatigue

fracture of the torque tube, followed by the failure of the

vertical stabilizer tip fairing brackets, which allowed the

horizontal stabilizer leading edge to move upward significantly

beyond what is permitted by a normally operating jackscrew

assembly. The resulting upward movement of the horizontal

stabilizer leading edge created an excessive upward aerodynamic

tail load, which caused an uncontrollable downward pitching of the

airplane from which recovery was not possible.

14. In light of the absence of a checklist requirement to land

as soon as possible and the circumstances confronting the flight

crew, the flight crew's decision not to return to Lic Gustavo Diaz

Ordaz International Airport, Puerto Vallarta, Mexico, immediately

after recognizing the horizontal stabilizer trim system malfunction

was understandable.

15.

The flight crew's decision to divert the flight to Los Angeles

International Airport, Los Angeles, California, rather than

continue to San Francisco International Airport, San Francisco,

California, as originally planned was prudent and appropriate.

15.

The flight crew's decision to divert the flight to Los Angeles

International Airport, Los Angeles, California, rather than

continue to San Francisco International Airport, San Francisco,

California, as originally planned was prudent and appropriate.

16. The flight crew's use of the autopilot while the horizontal

stabilizer was jammed was not appropriate.

17. The captain should have kept the slats and flaps

extended when the airplane was found to be controllable in that

configuration after the initial dive. (TO BE REVISED)

18. Without clearer guidance to flight crews regarding which

actions are appropriate and which are inappropriate in the event of

an inoperative or malfunctioning flight control system, pilots may

experiment with improvised troubleshooting measures that could

inadvertently worsen the condition of a controllable airplane.

19. The acme nut threads on the accident airplane's horizontal

stabilizer jackscrew assembly wore at an excessive rate.

20. Alaska Airlines' use of Aeroshell 33 for lubrication of the

jackscrew assembly, acme screw thread surface finish, foreign

debris, and abnormal loading of the acme nut threads were not

factors in the excessive wear of the accident acme nut threads.

21. There was no effective lubrication on the acme screw and nut

interface at the time of the Alaska Airlines flight 261

accident.

22. The excessive and accelerated wear of the accident jackscrew

assembly acme nut threads was the result of insufficient

lubrication, which was directly causal to the Alaska Airlines

flight 261 accident.

23. Alaska Airlines' extension of its lubrication interval for

its McDonnell Douglas MD-80 horizontal stabilizer components, and

the FAA's approval of that extension, the last of which was based

on Boeing's extension of the recommended lubrication interval

increased the likelihood that a missed or inadequate lubrication

would result in excessive wear of jackscrew assembly acme nut

threads and, therefore, was a direct cause of the excessive wear

and contributed to the Alaska Airlines flight 261 accident.

24. When lubricating the jackscrew assembly, removal of used

grease from the acme screw before application of fresh grease will

increase the effectiveness of the lubrication.

25. A larger access panel would facilitate the proper

accomplishment of the jackscrew assembly lubrication task.

26. If the jackscrew assembly lubrication procedure was a

required inspection item for which an inspector's signoff is

needed, the potential for unperformed or improperly performed

lubrications would be reduced.

27. Alaska Airlines' extension of the end play check interval,

and FAA's approval of the extension, allowed the accident acme nut

threads to wear to failure without the opportunity for detection

and, therefore, was a direct cause of the excessive wear and

contributed to the Alaska Airlines flight 261 accident.

28. Alaska Airlines' end play check interval extension should

have been, but was not, supported by adequate technical data to

demonstrate that the extension would not present a potential

hazard.

29. The existing process by which manufacturers revise

recommended maintenance task intervals and by which airlines

establish and revise these intervals does not include task-by-task

engineering analysis and justification and, therefore, allows for

the possibility of inappropriate interval extensions for

potentially critical maintenance tasks.

30.

Because of the possibility that higher-than-expected wear could

cause excessive wear in less than 2,000 flight hours and the

additional possibility that an end play check could be unperformed

or improperly performed, the current 2,000-flight-hour end play

check interval specified in Airworthiness Directive 2000-15-15 may

be inadequate to ensure the safety of the Douglas DC-9, McDonnell

Douglas MD-80/90, and Boeing 717 fleet.

30.

Because of the possibility that higher-than-expected wear could

cause excessive wear in less than 2,000 flight hours and the

additional possibility that an end play check could be unperformed

or improperly performed, the current 2,000-flight-hour end play

check interval specified in Airworthiness Directive 2000-15-15 may

be inadequate to ensure the safety of the Douglas DC-9, McDonnell

Douglas MD-80/90, and Boeing 717 fleet.

31. The continued collection and analysis of end play data are

critical to monitoring acme nut thread wear and identifying

excessive or unexpected wear rates, trends, or anomalies.

32. Until August 2000, Alaska Airlines used a fabricated

restraining fixture that did not meet Boeing specifications;

however, the Safety Board could not determine whether the use of

this noncompliant fixture generated an inaccurate end play

measurement during the last end play check or whether the use of

this fixture contributed to the accident.

33. The on-wing end play check procedure, as currently

practiced, has not been validated and has low reliability.

34. Deficiencies in the overhaul process increase the likelihood

that jackscrew assemblies may be improperly overhauled.

35. The absence of a requirement to record or inform customers

of the end play measurement of an overhauled jackscrew assembly

could result in an operator unknowingly returning a jackscrew

assembly to service with a higher-than-expected end play

measurement.

36. Operators will maximize the usefulness of end play

measurements and wear rate calculations by recording on-wing end

play measurements whenever a jackscrew assembly is replaced on an

airplane.

37. Because the jackscrew assembly is an integral and essential

part of the horizontal stabilizer trim system, a critical flight

system, it is important to ensure that maintenance facilities

authorized to overhaul these assemblies possess the proper

qualifications, equipment and documentation.

38. The dual-thread design of the acme screw and nut does not

provide redundancy with regard to wear.

39.

The design of the Douglas DC-9, McDonnell Douglas MD-80/90, and

Boeing 717 horizontal stabilizer jackscrew assembly did not account

for the loss of the acme nut threads as a catastrophic single-point

failure mode. The absence of a fail-safe mechanism to prevent the

catastrophic effects of total acme nut thread loss contributed to

the Alaska Airlines flight 261 accident.

39.

The design of the Douglas DC-9, McDonnell Douglas MD-80/90, and

Boeing 717 horizontal stabilizer jackscrew assembly did not account

for the loss of the acme nut threads as a catastrophic single-point

failure mode. The absence of a fail-safe mechanism to prevent the

catastrophic effects of total acme nut thread loss contributed to

the Alaska Airlines flight 261 accident.

40. When a failure could have catastrophic results, it is

not appropriate to rely on maintenance and inspection intervention

to prevent the failure from occurring if a practicable design

alternative could eliminate the catastrophic effects of the failure

mode. (TO BE REVISED)

41. Douglas DC-9, McDonnell Douglas MD-80/90, and Boeing 717

series airplanes, and if found necessary other transport category

airplanes, should be modified to ensure that loss of the horizontal

stabilizer trim system's jackscrew assembly acme nut threads or

other control assembly does not preclude continued safe flight and

landing.

42. Catastrophic single-point failure modes should be prohibited

in the design of all future airplanes with horizontal stabilizer

trim systems, regardless of whether any element of that system is

considered structure rather than system or is otherwise considered

exempt from certification standards for systems.

43. The certification requirements applicable to

transport-category airplanes should fully consider and address the

consequences of failures resulting from wear.

44. At the time of the flight 261 accident, Alaska Airlines'

maintenance program had widespread systemic deficiencies.

45. The FAA did not fulfill its responsibility to properly

oversee the maintenance operations at Alaska Airlines, and at the

time of the Alaska Airlines flight 261 accident, Federal Aviation

Administration surveillance of Alaska Airlines had been deficient

for at least several years.

Probable Cause

The National Transportation Safety Board determines that the

probable cause of this accident was a loss of airplane pitch

control resulting from the in-flight failure of the horizontal

stabilizer trim system jackscrew assembly's acme nut threads. The

thread failure was caused by excessive wear resulting from Alaska

Airlines' insufficient lubrication of the jackscrew assembly.

Contributing to the accident was

(1) Alaska Airlines' extended lubrication interval, and the FAA's

approval of that extension, which increased the likelihood that an

unperformed or inadequate lubrication would result in excessive

wear of the acme nut threads; and

(2) Alaska Airlines' extended end play check interval, and the

FAA's approval of that extension, which allowed the excessive wear

of the acme nut threads to progress to failure without the

opportunity for detection. Contributing also to the accident was

the absence on the MD-80 of a fail-safe mechanism to prevent the

catastrophic effects of total acme nut thread loss.

--

Perhaps even more-importantly in the long run, the NTSB had a

number of safety recommendations:

As a

result of the investigation of the Alaska Airlines flight 261

accident, the National Transportation Safety Board makes the

following recommendations to the Federal Aviation

Administration:

As a

result of the investigation of the Alaska Airlines flight 261

accident, the National Transportation Safety Board makes the

following recommendations to the Federal Aviation

Administration:

1. Issue a flight standards information bulletin directing air

carriers to instruct pilots that in the event of an inoperative or

malfunctioning flight control system, if the airplane is

controllable they should complete only the applicable checklist

procedures and should not attempt any corrective actions beyond

those specified. In particular, in the event of an inoperative or

malfunctioning horizontal stabilizer trim control system, after a

final determination has been made in accordance with the applicable

checklist that both the primary and alternate trim systems are

inoperative, neither the primary nor the alternate trim motor

should be activated, either by engaging the autopilot or using any

other trim control switch or handle. Pilots should further be

instructed that if checklist procedures are not effective, they

should land at the nearest suitable airport. (A-02-XX)

2. As part of the response to Safety Recommendation A-01-41,

require operators of Douglas DC-9, McDonnell Douglas MD-80/90, and

Boeing 717 series airplanes to remove degraded grease from the

jackscrew assembly acme screw and flush degraded grease and

particulates from the acme nut before applying fresh grease.

(A-02-XX)

3. As part of the response to Safety Recommendation A-01-41,

require operators of Douglas DC-9, McDonnell Douglas MD-80/90, and

Boeing 717 series airplanes, in coordination with Boeing, to

increase the size of the access panels that are used to accomplish

the jackscrew assembly lubrication procedure. (A-02-XX)

4. Establish the jackscrew assembly lubrication procedure as a

required inspection item that must have an inspector's signoff

before the task can be considered complete. (A-02-XX)

5.

Review all existing maintenance intervals for tasks that could

affect critical aircraft components and identify those that have

been extended without adequate engineering justification in the

form of technical data and analysis demonstrating that the extended

interval will not present any increased risk and require

modifications of those intervals to ensure that they (1) take into

account assumptions made by the original designers, (2) are

supported by adequate technical data and analysis, and (3) include

an appropriate safety margin that takes into account the

possibility of missed or inadequate accomplishment of the

maintenance task. In conducting this review, the Federal Aviation

Administration should also consider original intervals recommended

or established for new aircraft models that are derivatives of

earlier models and, if the aircraft component and the task are

substantially the same and the recommended interval for the new

model is greater than that recommended for the earlier model, treat

such original intervals for the derivative model as "extended"

intervals. (A-02-XX)

5.

Review all existing maintenance intervals for tasks that could

affect critical aircraft components and identify those that have

been extended without adequate engineering justification in the

form of technical data and analysis demonstrating that the extended

interval will not present any increased risk and require

modifications of those intervals to ensure that they (1) take into

account assumptions made by the original designers, (2) are

supported by adequate technical data and analysis, and (3) include

an appropriate safety margin that takes into account the

possibility of missed or inadequate accomplishment of the

maintenance task. In conducting this review, the Federal Aviation

Administration should also consider original intervals recommended

or established for new aircraft models that are derivatives of

earlier models and, if the aircraft component and the task are

substantially the same and the recommended interval for the new

model is greater than that recommended for the earlier model, treat

such original intervals for the derivative model as "extended"

intervals. (A-02-XX)

6. Conduct a systematic industrywide evaluation and issue a

report on the process by which manufacturers recommend and airlines

establish and revise maintenance task intervals and make changes to

the process to ensure that, in the future, intervals for each task

(1) take into account assumptions made by the original designers,

(2) are supported by adequate technical data and analysis, and (3)

include an appropriate safety margin that takes into account the

possibility of missed or inadequate accomplishment of the

maintenance task. (A-02-XX)

7. Require operators to supply the Federal Aviation

Administration, before the implementation of any changes in

maintenance tasks intervals that could affect critical aircraft

components, technical data and analysis for each task demonstrating

that none of the proposed changes will present any potential

hazards, and obtain written approval of the proposed changes from

the principal maintenance inspector and written concurrence from

the appropriate FAA aircraft certification office. (A-02-XX)

8. Pending the incorporation of a fail-safe mechanism in the

design of the Douglas DC-9, McDonnell Douglas MD-80/90, and Boeing

717 horizontal stabilizer jackscrew assembly, as recommended in

[Safety Recommendation 13 in this report], establish an end play

check interval that (1) accounts for the possibility of

higher-than-expected wear rates and measurement error in estimating

acme nut thread wear and (2) provides for at least two

opportunities to detect excessive wear before a potentially

catastrophic wear condition becomes possible. (A-02-XX)

9. Require operators to permanently (1) track end play measures

according to airplane registration number and jackscrew assembly

serial number, (2) calculate and record average wear rates for each

airplane based on end play measurements and flight times, and (3)

develop and implement a program to analyze these data to identify

and determine the cause of excessive or unexpected wear rates,

trends, or anomalies. The Federal Aviation Administration (FAA)

should also require operators to report this information to the FAA

for use in determining and evaluating an appropriate end play check

interval. (A-02-XX)

10. Require that maintenance facilities that overhaul jackscrew

assemblies record and inform customers of an overhauled jackscrew

assembly's end play measurement. (A-02-XX)

11. Require operators to measure and record the on-wing end play

measurement whenever a jackscrew assembly is replaced.

(A-02-XX)

12. Require that maintenance facilities that overhaul Douglas

DC-9, McDonnell Douglas MD-80/90, and Boeing 717 series jackscrew

assemblies obtain specific authorization to perform such overhauls,

predicated on demonstrating that they possess the necessary

capability, documentation, and equipment for the task and that they

have procedures in place to (1) perform and document the detailed

steps that must be followed to properly accomplish the end play

check procedure and lubrication of the jackscrew assembly,

including specification of appropriate tools and grease types; (2)

perform and document the appropriate steps for verifying that the

proper acme screw thread surface finish has been applied; and (3)

ensure that appropriate packing procedures are followed for all

returned overhauled jackscrew assemblies, regardless of whether the

assembly has been designated for storage or shipping. (A-02-XX)

13. Conduct a systematic engineering review of all transport

category airplanes to identify means to eliminate the catastrophic

effects of a system or associated structure failure in the

horizontal stabilizer trim system jackscrew assembly, and, if

practical, that all future transport category airplanes incorporate

such fail-safe mechanisms. (A-02-XX) (TO BE REVISED)

14. Modify the certification regulations, policies, or

procedures to ensure that new horizontal stabilizer trim control

system designs are not certified if they have a single-point

catastrophic failure mode, regardless of whether any element of

that system is considered structure rather than system or is

otherwise considered exempt from certification standards for

systems. (A-02-XX)

15. Review and revise aircraft certification

regulations and associated guidance applicable to the certification

of transport-category airplanes to ensure that wear-related

failures are fully considered and addressed so that, to the maximum

extent possible, they will not be catastrophic. (A-02-XX)

15. Review and revise aircraft certification

regulations and associated guidance applicable to the certification

of transport-category airplanes to ensure that wear-related

failures are fully considered and addressed so that, to the maximum

extent possible, they will not be catastrophic. (A-02-XX)

16. Issue a Flight Safety Information Bulletin directing air

carriers to discourage their dispatch and maintenance control

personnel from engaging in in-flight trouble shooting. (A-02-XX)

(TO BE REVISED)

[That's what happened, according to the best accident

investigators in the world. Now, the lawyers will tell juries what

"really" happened, as they look for the deepest pockets (to empty

into their own). Thus, money that could be spent on improving

safety will be used to pay off "punitive" lawsuits, helping ensure

a long-lasting revenue stream of blood money to law

firms --ed.]

ANN's Daily Aero-Term (12.13.25): Light Gun

ANN's Daily Aero-Term (12.13.25): Light Gun Aero-News: Quote of the Day (12.13.25)

Aero-News: Quote of the Day (12.13.25) NTSB Final Report: Gippsland GA-8

NTSB Final Report: Gippsland GA-8 Classic Aero-TV: Historically Unique -- Marlin Horst's Exquisite Fairchild 71

Classic Aero-TV: Historically Unique -- Marlin Horst's Exquisite Fairchild 71 Airborne 12.12.25: Global 8000, Korea Pilot Honors, AV-30 Update

Airborne 12.12.25: Global 8000, Korea Pilot Honors, AV-30 Update