Aero-Tips!

A good pilot is always learning -- how many times have you heard

this old standard throughout your flying career? There is no truer

statement in all of flying (well, with the possible exception of

"there are no old, bold pilots.")

Aero-News has called upon the expertise of Thomas P. Turner,

master CFI and all-around-good-guy, to bring our readers -- and us

-- daily tips to improve our skills as aviators. Some of them, you

may have heard before... but for each of us, there will also be

something we might never have considered before, or something that

didn't "stick" the way it should have the first time we memorized

it for the practical test.

Look for our daily Aero-Tips segments, coming each day to you

through the Aero-News Network.

Aero-Tips 11.14.06

Fuel Vents... UNOBSTRUCTED. It's a common step on an airplane's

Preflight Inspection checklist. But what are you really looking

for? Why is it so important to check fuel vents for

obstruction?

Tank types

There are three main types of fuel tank commonly installed in

general aviation airplanes (note: some airplane models may have

more than one type of tank installed):

- Bladder-type tanks-flexible rubber tanks, like big, thick

"balloons" in the wings or fuselage.

- Metal or fiberglass tanks-sealed containers for fuel set into

the wings or fuselage.

- "Wet wings" -- portions of the wing structure themselves that

are sealed to contain fuel and prevent leakage.

Fuel vents

Just like a portable gas tank for a lawn mower or boat, your

airplane's fuel tank requires a "push" of air pressure to keep fuel

flowing toward the engine. A blocked fuel vent can cause a vapor

lock that cuts off fuel flow -- causing a fuel starvation engine

failure even when there's a lot of fuel remaining in the tank.

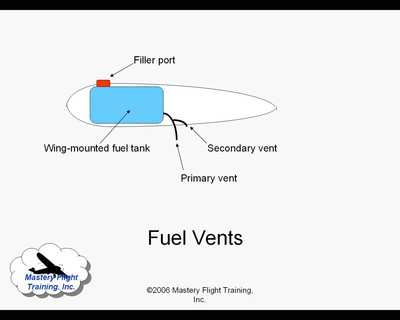

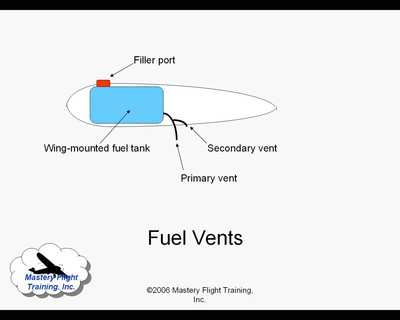

Fuel vents come in many designs and location, but usually

consist of a stick, or probe, extending below the wing or fuselage.

Orientation of the vent is critical -- if it is not properly

slanted into the slipstream it may actually create suction from the

tank, instead of pressure into it.

Each individual fuel tank may have its own vent, or several

tanks may plumb into a single vent line. Secondary vents may be

recessed in the wing, or consist of a simple hole drilled in the

aft side of the primary vent. Secondary vents are your back-up in

case bugs, dirt or ice block the primary.

Fuel tanks have another reason for proper venting. If a vent

becomes obstructed the suction created by a fuel pump (or even a

carbureted engine) can be so great that the tank collapses.

Bladder tanks may bunch up so fuel can't get from parts of the tank

into the engine; hard tanks can dimple and bend; and wet wings may

collapse to the point the airfoil shape is disrupted and

aerodynamics severely compromised.

A metal "tip tank" that collapsed in

flight under the suction of fuel draw, after its vent line was

obstructed by an insect. (photo courtesy American Bonanza

Society)

Few Pilots Operating Handbooks tell precisely where fuel tank

vents are located, how they need to be oriented, whether they have

secondary holes that must also be open, or even how many fuel vents

there are on the airplane. Your best bet is to contact a user group

("type club") for your

particular airplane type for the proper tank vent inspection

requirements.

Aero-tip of the day: Check fuel vents for orientation and lack

of obstruction during every preflight check.

NTSB Final Report: Cozy Cub

NTSB Final Report: Cozy Cub ANN FAQ: Contributing To Aero-TV

ANN FAQ: Contributing To Aero-TV Classic Aero-TV: Seated On The Edge Of Forever -- A PPC's Bird's Eye View

Classic Aero-TV: Seated On The Edge Of Forever -- A PPC's Bird's Eye View ANN's Daily Aero-Linx (04.29.25)

ANN's Daily Aero-Linx (04.29.25) ANN's Daily Aero-Term (04.29.25): Execute Missed Approach

ANN's Daily Aero-Term (04.29.25): Execute Missed Approach