Will Also Be Used For Ares Rockets

NASA's Space Shuttle Program successfully fired a reusable

solid rocket motor Thursday, May 24, at a Utah test facility. The

space agency tells ANN the two-minute test provided important

information for continued shuttle launches, and for development of

the rocket that will carry the next human spacecraft to the

moon.

NASA's Space Shuttle Program successfully fired a reusable

solid rocket motor Thursday, May 24, at a Utah test facility. The

space agency tells ANN the two-minute test provided important

information for continued shuttle launches, and for development of

the rocket that will carry the next human spacecraft to the

moon.

The static firing of the full-scale, full-duration flight

support motor was performed at 1 p.m. MDT at ATK Launch Systems

Group, a unit of Alliant Techsystems Inc. in Promontory, UT where

the shuttle's solid rocket motors are manufactured.

The flight support motor, or FSM-14, burned for approximately

123 seconds, the same time each reusable solid rocket motor burns

during an actual space shuttle launch. The Reusable Solid Rocket

Booster Project Office at NASA's Marshall Space Flight Center in

Huntsville, AL manages these tests to qualify any proposed changes

to the rocket motor and to determine whether new materials perform

as well as those now in use.

"Full-scale static testing such as this is a key element of the

'test before you fly' standard and ensures continued quality and

performance," said Jody Singer, manager of the Reusable Solid

Rocket Booster Project, part of the Space Shuttle Propulsion Office

at Marshall.

Thursday's test provided data on numerous process, material and

design changes planned for shuttle solid rocket motors, including

obtaining performance data on a new low-temperature O-ring seal

material for improved sealing capabilities and a new nozzle liner

material and asbestos-free case insulation material.

The shuttle solid rocket motor firing also supports NASA's

future exploration goals to return humans to the moon. The test

provided data for development of the first stage solid rocket motor

for NASA's Ares I, the launch vehicle that will carry the Orion

spacecraft and its astronaut crew to Earth orbit. Engineers with

NASA's Exploration Launch Projects Office at Marshall, which

manages the Ares launch vehicles, will analyze motor-generated

external loads in support of continued Ares I design efforts. They

also will review the data gathered on the O-rings and

insulation.

Preliminary indications are that all test objectives were met.

After final test data are analyzed, results for each objective will

be published by NASA in a report available late this year.

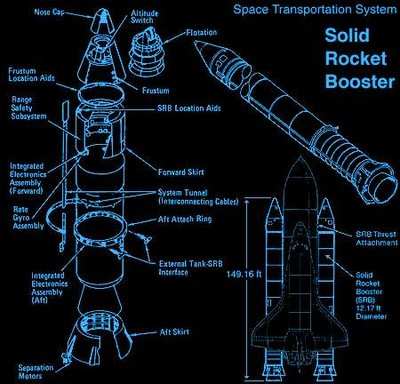

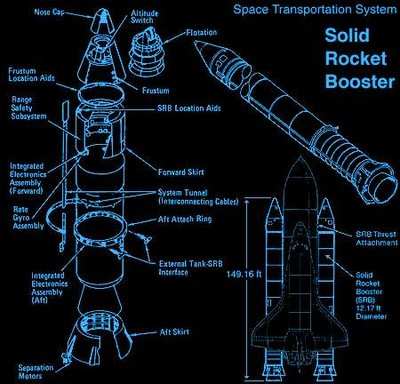

The shuttle's reusable solid rocket motor is the largest solid

rocket motor ever flown, the only one rated for human flight and

the first designed for reuse. Each shuttle launch requires two

reusable solid rocket motors to lift the 4.5-million-pound shuttle.

The motors provide 80 percent of the thrust during the first two

minutes of flight. Each motor, just over 126 feet long and 12 feet

in diameter, generates an average thrust of 2.6 million pounds. It

is the primary component of the shuttle's twin solid rocket

boosters.

During a shuttle launch, the rockets take the shuttle to an

altitude of 28 miles at a speed of 3,094 mph before they separate

and fall into the ocean. Then they are retrieved, refurbished and

prepared for another flight.

Regular static-fire tests of the motors help maintain the

highest safety, quality and reliability standards of solid rocket

motors used for human spaceflight. Engineers conduct approximately

110,000 quality-control inspections on each motor designed for

flight.

ANN's Daily Aero-Linx (05.06.25)

ANN's Daily Aero-Linx (05.06.25) ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF)

ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF) ANN FAQ: Q&A 101

ANN FAQ: Q&A 101 Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training

Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance

Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance