Company Decides Who'll Do What When 7E7 Comes Off Drawing

Board

Boeing Thursday announced work share arrangements for the team

that will be responsible for major structural sections of its

proposed 7E7 Dreamliner.

The structures team partners, named earlier this year, will

build large sections of the airplane at sites in the United States,

Japan, Italy, Australia and Canada, then transport those parts to

the 7E7 final assembly location in the United States.

Boeing will provide major structure

to the program through work at its facilities in Frederickson (WA),

Tulsa (OK), Wichita (KS), and Winnipeg, Canada; and at Hawker de

Havilland in Australia. Other work packages have been assigned to

Japan's Fuji Heavy Industries (FHI), Kawasaki Heavy Industries

(KHI), and Mitsubishi Heavy Industries (MHI), Vought Aircraft

Industries in Dallas (TX)and Italy's Alenia Aeronautica.

Boeing will provide major structure

to the program through work at its facilities in Frederickson (WA),

Tulsa (OK), Wichita (KS), and Winnipeg, Canada; and at Hawker de

Havilland in Australia. Other work packages have been assigned to

Japan's Fuji Heavy Industries (FHI), Kawasaki Heavy Industries

(KHI), and Mitsubishi Heavy Industries (MHI), Vought Aircraft

Industries in Dallas (TX)and Italy's Alenia Aeronautica.

"The process of assigning work packages has been very thorough

and deliberate," said Mike Bair, senior vice president of the 7E7

program. "We looked at the capabilities and capacities of each

structures team partner and assigned work where it would be done

efficiently and effectively, creating a great product for our

customers and solid business cases for everyone involved."

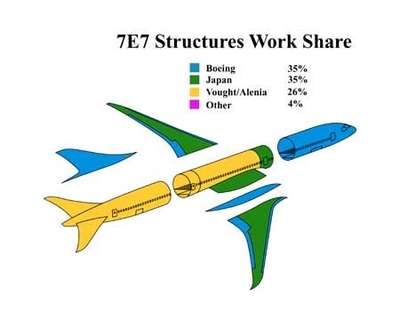

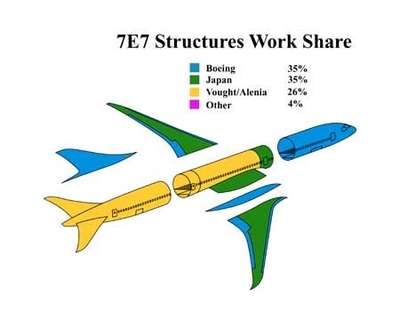

Boeing will supply approximately 35 percent of the 7E7 structure

including the vertical fin from Frederickson, the fixed and movable

leading edges of the wing from Tulsa, the flight deck and part of

the forward fuselage section from Wichita, the movable trailing

edges from Australia and the wing-to-body fairing from

Winnipeg.

MHI will be responsible for the wing box. KHI will provide the

remaining part of the forward fuselage, the main landing gear wheel

well and the main wing fixed trailing edge. FHI is focused on the

center wing box and integration of the center wing box with the

main landing gear wheel well. The total work share of the 7E7

structure for Japan is approximately 35 percent.

Vought and Alenia are teaming on

their work packages, with details of where they will build

different elements expected at a later date. Together, they will

build the 7E7 horizontal stabilizer and the center and aft

fuselage. The Vought/Alenia work statement accounts for

approximately 26 percent of the 7E7 structure.

Vought and Alenia are teaming on

their work packages, with details of where they will build

different elements expected at a later date. Together, they will

build the 7E7 horizontal stabilizer and the center and aft

fuselage. The Vought/Alenia work statement accounts for

approximately 26 percent of the 7E7 structure.

Discussions regarding the placement of the remaining structures

work are ongoing. This work accounts for approximately 4 percent of

the 7E7 structure.

"This is a great team of proven performers," said Bair. "I look

forward to our ongoing cooperation as we move forward with the 7E7.

These decisions take us one step closer to our Authority to Offer

review with our board of directors."

Boeing today confirmed that the 7E7 program headquarters and

development and design integration center will be in Everett,

Wash.

Boeing announced earlier this year that final assembly will be

in the United States and is continuing with the process of

evaluating proposals received by potential final assembly

locations.

The company expects to make decisions regarding the placement of

7E7 systems and other work throughout 2004. A decision regarding

which engine or engines will be offered on the airplane is expected

in mid-2004.

"Creating a new airplane is a tremendous undertaking," said

Bair. "We have worked diligently with our partners and our Boeing

sites to find the answers that will ensure the success of the

program."

ANN's Daily Aero-Linx (05.06.25)

ANN's Daily Aero-Linx (05.06.25) ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF)

ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF) ANN FAQ: Q&A 101

ANN FAQ: Q&A 101 Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training

Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance

Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance