An Update On The Amazing CarterCopter Program

By ANN Correspondent Kevin "Hognose" O'Brien

How're They Doing

After the rebuild and four months into the flight program, the

CarterCopter has reached a speed of 142 mph and a Mu of .62. This

is not close to the previous best (Mu = 0.87, speet 173 kt,

Altitude 10,000) but the test program is going slowly. The machine

has achieved a rate of climb of 750 fpm at 4,000 lb (as a standard

for comparison, most gyroplanes weigh a few hundred pounds, with

only such heavyweights as the RAF 2000 and AAI Sparrowhawk breaking

1,000). This rate of climb figure was with the gear down.

The attempt to break the Mu=1.0 barrier, announced last summer,

will be rescheduled when the test program is far enough along. "I

want six months of consistent flight before I schedule all that

again," Anita told Aero-News. "All that" being the events at the

Texas International Speedway that will accompany the Mu 1

attempt.

Another significant accomplishment of the demonstrator is

achieving a rotor RPM of 115. "115 is what we've gotten. 60 is

lowest theoretically conceivable - it would go unstable and

divergent and lean. 100 is as low as we will recommend." Slowing

the rotor down is a key to high-speed flight; in the CarterCopter

the rotor is gradually unloaded and the little wings take more of

the flight loads until they are supplying all of the lift and the

rotor is almost completely unloaded. "We use the rotor as the

ultimate high-lift device," Jay said. "We don't worry about loss of

control, as with the rotor we can fly as slow as necessary." At the

same time the wing need only be sized for high-speed flight; it

need not have the compromises that jet wings have. "I'm confident

that we can beat turboprop planes for speed, door to door."

"Slowing the rotor down is not new. They did tests on a Pitcairn

with wings in 1934 - they couldn't control the flapping." So what

has changed since 1934? We know a lot more about aerodynamics and

about rigid structures; it is possible to make something that could

only be conceptualized 70 years ago.

The tilting mast is another Carter innovation, and it's

particularly useful on a winged gyro. The mast tilts forward for

jump takeoff. There's a slight tilt back for autorotating cruise,

and a greater tilt back for auto to landing. The rotor thrust

vector is always aimed where it needs to be, the axis always runs

through CG, and the aircraft always is level - that means that for

the first time since wings have been invented, the wing is at best

L/D over the machine's entire speed range! Once again Jay's

explanation was needed. "It is automatic. As he goes faster he

pushes forward on the stick. As we tilt this rotor - less driving

force - lift drops off. The pilot doesn't realize this is

happening. It's not 100% efficient -- we have a little trim on the

control to keep SOME rotation at all times.

G-Force Landing Gear - Spectacularly Safe

The evolutionary ultralight Butterfly gyroplane that Larry

Neal's The Butterfly, LLC, introduced at Oshkosh last August has

grown into the revolutionary Monarch experimental with the addition

of more power (Rotax 582 instead of 277) and a landing gear design

by Neal using Carter's patented Smart Strut technology.

As installed on the gyro, the landing gear resulted from an

unpleasant experience Larry had. He landed hard in a regular gyro

and bent the axle. Most guys would have cursed and replaced the

axles. Larry cursed, replaced the axle, and thought about how the

bent axle absorbed some of the impact energy. What if you could

deform an axle like that, or rather, have some way to absorb the

energy - you could eliminate, Larry immediately saw, one of the

largest contributing factors in gyro mishaps. He thought of the

struts technology used in the Carter Copter Technology

Demonstrator.

The landing gear in the CCTD has been proof-tested up to 1200

feet-per-minute descents to contact at 3000 lb gross weight. The

landing gear in the Monarch has been flight-tested up to 800

feet-per-minute, which would result in substantial damage and

personal injury in a conventional gyro. "It's like sitting down in

a couch," Larry said.

The landing gear as now installed is a parallelogram swing arm

system. It looks a bit like the gear in an Extra 400, or Lockheed

F104, or Grumman F4F Wildcat - except with an eye-poking long

stroke. This makes the gear dangle like a droopy moustache while

the gyro is inflight, even though it is basically parallel to the

ground when at rest on the ground. The parallelogram structure of

the landing gear legs, almost like a Formula 1 racing suspension,

holds the wheels vertical throughout the long travel of the landing

gear (16 inches at the wheels). This design absorbs unprecedented

amounts of energy. It neither allows the energy to damage the

structure or generate a destructive bounce; even at the highest

rates of descent, the gyro simply squats.

After the press conference, Jay took the time one-on-one to make

sure that I understood how the Smart Strut worked. The key to safe

deceleration is that the strut absorbs energy and decelerates the

downward motion of the aircraft at a steady rate over the entire

long stroke (16 inches) of the gear. At the extreme stroke of the

strut, the valve closes, so there is no bounce-back. This accounts

for the jaw-dropping way the Monarch can simply plunge to the

ground, and stick there. Larry, Jay, and company have answered the

age-old question, "How come we can put a man on the moon but we

can't make a bounce-proof, energy-absorbing landing gear?"

The Smart Strut as used in the G-Force landing gear is the first

example of a Carter technology that has been licensed by another

company, The Butterfly, LLC. Carter Aviation Technologies is

actively seeking more customers for this technology, which is

adaptable to fixed-wing and rotary-wing aircraft.

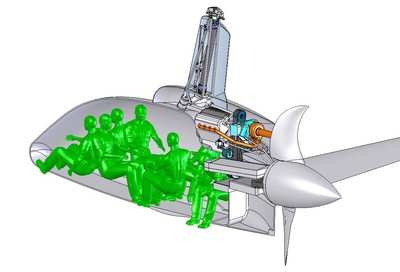

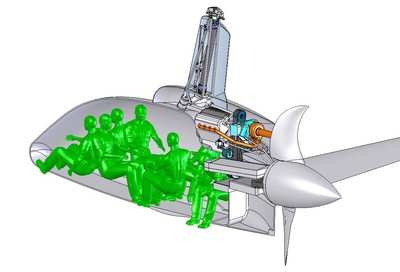

NASA SATS/Personal Air Vehicle Contract

Everybody knows that Carter Aviation Technologies is a space-age

company, but a few eyebrows went up when they were exhibiting in

the NASA tent at S-n-F. But there was a good reason: Carter has

received a Phase I research grant to develop a preliminary Personal

Air Vehicle based on CarterCopter technology. Design goals are

VTOL, 200 mph speeds, and a 1000-mile range.

Georgia Tech's Aerospace Systems Design Lab (GT/ASDL), which is

also getting involved with other Carter projects, will be doing the

data collection, analysis, and tool development. Georgia Tech

states the question this way: Can the angular velocity of a lifting

rotor in autorotation be significantly slowed to radically reduce

drag in high advance-ratio flight while maintaining dynamic

stability.

Or, in plain English, "Can the CarterCopter concept really lead

to a revolution in S/VTOL, high-speed flight?"

The Georgia Tech investigators cautiously suggest that, "The

slowed-rotor / compound appears to have the potential to exceed the

performance of conventional rotorcraft while at the same time

reducing the complexity and cost." In order for that to be known, a

lot of data needs to be gathered and analyzed, and analysis tools

for the job need to be validated - or even crafted from scratch.

That's what this contract's all about.

While certification of a Personal Air Vehicle would be a long,

drawn-out, and not least, expensive process, a kit might be more

viable. Carter's estimate for the cost of a kit, less engine and

instruments, is about $55,000 (less engine and avionics), if 1000

kits are made yearly. To put that in perspective, that number is

five to ten times the number of kit gyros being completed and

licensed every year, now. But a Carter PAV's appeal stretches out

beyond the small, insular gyro community. Will it happen? Probably

not after one study… but since when did a study ever reach

any conclusion, but that another study is needed?

Army Contract

At the press conference, Jay remembered the December 2003 demo

for Army officers with wry humor. "We demonstrated in front of six

bigwigs from the Army, did a nice demo, and capped it off with

wheels-up landing. Tore the aircraft up pretty bad." The Army

apparently looked past the accident, a result of pilot error when

the pilot's workload went severely nonlinear, and was able to see

the promise of the underlying technology, because Carter has a new

military contract with the Army. (Of course, the new automation

helps the workload problem, too). The contract provides research on

inflight technology (in other words, for test flights, not just

paper studies) and is fiscal 2004 funding.

The contract can run up to $1,000,000 and may (or may not) lead

to further contracts.

The Army wants the good and the bad news: not only whether

CarterCopter technology can surpass the performance of helicopters

(particularly in range and speed), but also what, if any, are the

particular limitations of this technology. One thing they will be

looking hard at is the efficiency of the rotor, wing, and propeller

across the whole range of operations. Like the SATS/PAV contract

for NASA, one by-product of this is likely to be better analysis

tools and models for such unusual rotorcraft and the novel flight

regimes they reach.

Some More Things…

…that didn't fit easily into the four major sections of

this story.

- Jay Carter Jr. has done

an interview for EAA's "Timeless Voices of Aviation" oral history

series (along with ANN E-I-C Jim Campbell).

- Larry Neal doesn't just fly for a living, but he's on a

personal crusade for gyro safety after a flying buddy tumbled to

death in a kit gyroplane with known stability issues.

- Design has begun on NxCC, the next generation Carter Copter.

Objective: Take off from downtown LA, land downtown NYC without

refueling.

- The CarterCopter is featured on the BritishAirways inflight

magazine in the month of May.

- In the past, Jay Carter Jr. has always insisted that Carter

Aviation Technologies is a technology company, which will profit by

licensing technologies, not a products company that will build

stuff based on that technology. He has always adamantly opposed a

Carter-produced aircraft, for instance. But at this press

conference he indicated that Carter Aviation Technologies might

consider producing a personal CarterCopter in kit or flying form,

in order to kick-start adoption of the technology.

To Cap and Recap

It's hard keeping up with Carter Aviation Technologies, even

when you're a mere scribe and all you're trying to do is write down

the ideas that come percolating out of Wichita Falls, TX. You don't

have to have been bitten by the gyro bug to recognize that much of

the most revolutionary thought in aviation is in and around this

project. Will history say that Jay Carter Jr. and his team changed

the course of aviation? Or will history record him as one of the

might-have-beens whose headstones stand in the graveyard of VTOL

concepts? I think and hope that the first of those questions is the

one that gets a "yes". But regardless of how that comes out, what

they are doing today is making history.

ANN's Daily Aero-Linx (05.06.25)

ANN's Daily Aero-Linx (05.06.25) ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF)

ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF) ANN FAQ: Q&A 101

ANN FAQ: Q&A 101 Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training

Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance

Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance