Tue, Jun 03, 2003

Advertisement

More News

NTSB Final Report: Aviat A1

NTSB Final Report: Aviat A1

Airplane Bounced About 3 Ft Then Touched Back Down And Then, With No Brakes Applied, The Airplane Began Veering To The Left Analysis: The pilot entered the airport traffic pattern >[...]

ANN's Daily Aero-Linx (07.08.25)

ANN's Daily Aero-Linx (07.08.25)

Aero Linx: British Microlight Aircraft Association (BMAA) The primary focus within all aviation activity is SAFETY. In all aspects of our sport SAFETY must come first, whether it b>[...]

Classic Aero-TV: Fly Corvairs Reliable Engine Alternative

Classic Aero-TV: Fly Corvairs Reliable Engine Alternative

From SnF25 (YouTube Edition): William Wynne Builds Practical Aircraft Engines on the Corvair Platform Seeking an affordable alternative to the traditional aircraft engine options, >[...]

ANN FAQ: Contributing To Aero-TV

ANN FAQ: Contributing To Aero-TV

How To Get A Story On Aero-TV News/Feature Programming How do I submit a story idea or lead to Aero-TV? If you would like to submit a story idea or lead, please contact Jim Campbel>[...]

Classic Aero-TV: CiES Fuel-Quantity and e-Throttle Systems Praised

Classic Aero-TV: CiES Fuel-Quantity and e-Throttle Systems Praised

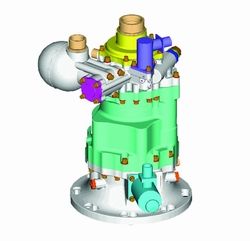

From 2023 (YouTube Edition): Bridge of CiES CiES Inc. is a Bend, Oregon-based designer and manufacturer of modular embedded aircraft systems and sensors. The company’s fuel-l>[...]

blog comments powered by Disqus