Cold Spray Technology Will Be First In The Country Used For Structural Repair Of Commercial Aircraft Parts

Faster, market competitive, and safer airplane repairs. That's the goal of a project by The University of Akron and Airborne Maintenance and Engineering Services in obtaining FAA approval for "cold spray" repair of corroded and worn parts on commercial aircraft.

Promising demonstrations and test results of this application were showcased Monday at the Airborne Maintenance and Engineering Services at the Wilmington Air Park. Members of the Ohio General Assembly – including Speaker of the Ohio House of Representatives Cliff Rosenberger and Ohio Senate President Pro Tempore Bob Peterson – viewed progress of Supersonic Particle Deposition (SPD), a groundbreaking aircraft repair method for applying metal particles to rebuild the surfaces of corroded and worn parts. By extending the useful life of an aircraft's parts, this public-private partnership initiative is anticipated to lead to the first FAA certification for full-scale commercial aircraft repair operations. For a region that is actively expanding the job market by developing emerging technology to grow the aviation sector, this approval is another step forward in additional jobs and economic development opportunities.

The technique involves a high pressure spraying process in which metal particles contained in a supersonic jet of an expanded gas impact a solid surface with sufficient energy to cause bonding with the surface. This additive manufacturing process builds up and repairs the surface of the metal part without creating a heat-affected zone that would occur during welding or high temperature thermal spray.

Development and testing has been underway for two years, funded by the Ohio Legislature in the last Operating Budget, and supported by The University of Akron's National Center for Education and Research on Corrosion and Materials Performance (NCERCAMP) in collaboration with Airborne Maintenance and Engineering Services (AMES), SAFEngineering, Inc., and U.S. Technology Corporation. The data gathered has provided the foundation required for FAA approval of SPD dimensional restoration of aircraft structure.

This collective effort has produced numerous achievements with the SPD technology highlighting the effectiveness of public-private partnerships for economic growth. Once the goal of this program is attained, the application of the process is limitless across the commercial aviation sector.

"This technology in commercial applications creates significant ongoing opportunities for economic advancement in Ohio through advanced manufacturing and job growth," said Greg Smith, Director, Engineering for Airborne Maintenance and Engineering Services.

UA's Corrosion Engineering program is the first of its kind in the United States. Housed at The University of Akron, NCERCAMP provides a multi-disciplinary approach to help government and industry develop solutions for corrosion and materials performance challenges. In response to requests from private industry and the Department of Defense in 2006, The University of Akron launched an effort to help address the cost of corrosion on the nation's economy, estimated at more than $400 billion annually. In 2010, NCERCAMP was established by Congress and the U.S. Department of Defense.

"We are grateful for the support that the State of Ohio has provided for this first phase of the SPD project which is making significant progress," said Rex Ramsier, UA's senior vice president and provost. "This partnership brings together the University's expertise in corrosion and materials science with the extensive experience that our partners have in aviation and technology to create an exciting opportunity for job creation and technological advancement in Ohio."

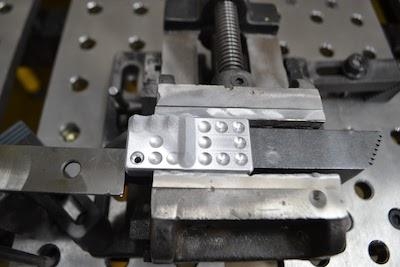

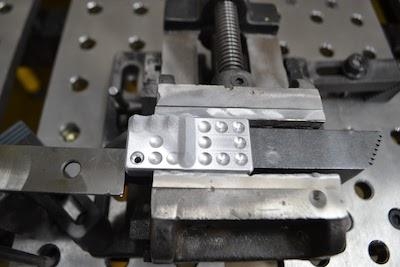

(Images provided with University of Akron news release. Top: Supersonic Particle Deposition (SPD) booth, where a robotic arm is programmed to apply cold spray technology to repair surface of corroded aircraft parts. Bottom: An aluminum domino is a before/after demonstration of how the Supersonic Particle Deposition (SPD), also known as Cold Spray, applies metal particles to a worn part)

Airborne 07.21.25: Nighthawk!, Hartzell Expands, Deltahawk 350HP!

Airborne 07.21.25: Nighthawk!, Hartzell Expands, Deltahawk 350HP! ANN's Daily Aero-Term (07.27.25): Estimated (EST)

ANN's Daily Aero-Term (07.27.25): Estimated (EST) ANN's Daily Aero-Linx (07.27.25)

ANN's Daily Aero-Linx (07.27.25) NTSB Final Report: Luce Buttercup

NTSB Final Report: Luce Buttercup Classic Aero-TV: 'That's All Brother'-Restoring a True Piece of Military History

Classic Aero-TV: 'That's All Brother'-Restoring a True Piece of Military History