Tue, Jul 05, 2011

Accuracies Of Less Than One-Millionth Of An Inch Required

Mirrors are a critical part of a telescope. The quality is

crucial, so completion of mirror polishing represents a major

milestone. All of the mirrors that will fly aboard NASA's James

Webb Space Telescope have been polished so the observatory can see

objects as far away as the first galaxies in the universe.

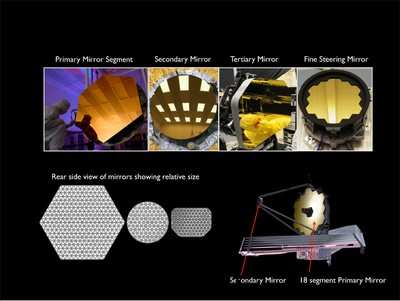

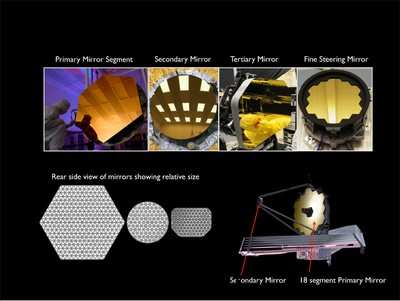

The Webb telescope is comprised of four types of mirrors. The

primary one has an area of approximately 29.9 square yards, which

will enable scientists to capture light from faint, distant objects

in the universe faster than any previous space observatory. The

mirrors are made of Beryllium and will work together to relay

images of the sky to the telescope's science cameras. "Webb's

mirror polishing always was considered the most challenging and

important technological milestone in the manufacture of the

telescope, so this is a hugely significant accomplishment," said

Lee Feinberg, Webb Optical Telescope manager at NASA's Goddard

Space Flight Center in Greenbelt, MD.

The mirrors were polished at the L3 Integrated Optical Systems -

Tinsley in Richmond, CA. to accuracies of less than one millionth

of an inch. That accuracy is important for forming the sharpest

images when the mirrors cool to -400 degrees F (-240 degrees C) in

the cold of space. "The completion of the mirror polishing shows

that the strategy of doing the hardest things first has really paid

off," said Nobel Prize Winner John C. Mather, Webb's senior project

scientist at Goddard. "Some astronomers doubted we could make these

mirrors."

After polishing, the mirrors are being coated with a

microscopically thin layer of gold to enable them to efficiently

reflect infrared light.

NASA has completed coating 13 of 18 primary mirror segments and

will complete the rest by early next year. The 18 segments fit

together to make one large mirror 21.3 feet across. "This milestone

is the culmination of a decade-long process," said Scott

Willoughby, vice president and Webb Telescope Program manager for

Northrop Grumman Aerospace Systems. "We had to invent an entire new

mirror technology to give Webb the ability to see back in

time."

More News

Airplane Bounced About 3 Ft Then Touched Back Down And Then, With No Brakes Applied, The Airplane Began Veering To The Left Analysis: The pilot entered the airport traffic pattern >[...]

Aero Linx: British Microlight Aircraft Association (BMAA) The primary focus within all aviation activity is SAFETY. In all aspects of our sport SAFETY must come first, whether it b>[...]

From SnF25 (YouTube Edition): William Wynne Builds Practical Aircraft Engines on the Corvair Platform Seeking an affordable alternative to the traditional aircraft engine options, >[...]

How To Get A Story On Aero-TV News/Feature Programming How do I submit a story idea or lead to Aero-TV? If you would like to submit a story idea or lead, please contact Jim Campbel>[...]

From 2023 (YouTube Edition): Bridge of CiES CiES Inc. is a Bend, Oregon-based designer and manufacturer of modular embedded aircraft systems and sensors. The company’s fuel-l>[...]

NTSB Final Report: Aviat A1

NTSB Final Report: Aviat A1 ANN's Daily Aero-Linx (07.08.25)

ANN's Daily Aero-Linx (07.08.25) Classic Aero-TV: Fly Corvairs Reliable Engine Alternative

Classic Aero-TV: Fly Corvairs Reliable Engine Alternative ANN FAQ: Contributing To Aero-TV

ANN FAQ: Contributing To Aero-TV Classic Aero-TV: CiES Fuel-Quantity and e-Throttle Systems Praised

Classic Aero-TV: CiES Fuel-Quantity and e-Throttle Systems Praised