Discovery Could Ignite "Engine Of The Future"

Researchers at Tufts University have

discovered that it's possible to make hydrogen from fossil fuels

using far less platinum or gold than current fuel processing

technology has required. Their research shows that 90 percent of

precious metals used today may be removed from the catalyst without

affecting its ability to produce hydrogen.

Researchers at Tufts University have

discovered that it's possible to make hydrogen from fossil fuels

using far less platinum or gold than current fuel processing

technology has required. Their research shows that 90 percent of

precious metals used today may be removed from the catalyst without

affecting its ability to produce hydrogen.

This finding could have potential cost savings of millions of

dollars in the materials required to commercialize the fuel cell

technology.

The research will be published in the July 3 edition of

"Science Express," the online version of the journal

Science that provides rapid electronic publication of

timely and important research papers. The article also will be

published in Science later this summer.

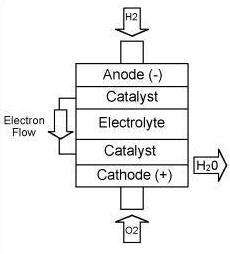

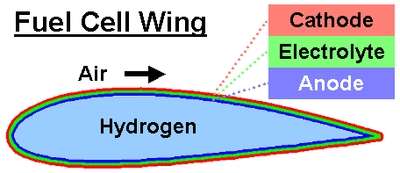

A fuel cell consists of two

electrodes sandwiched around an electrolyte. Hydrogen fed to the

one electrode (anode) passes through the electrolyte in the form of

protons and combines with oxygen on the other electrode (cathode)

making water and producing heat. Electricity is generated in the

process. A fuel cell will produce energy in the form of electricity

and heat as long as fuel and oxygen are supplied. To produce

fuel-cell quality hydrogen, an important step involves the removal

of any by-product carbon monoxide, which poisons the fuel cell

anode catalyst.

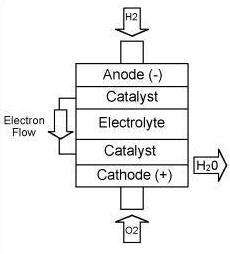

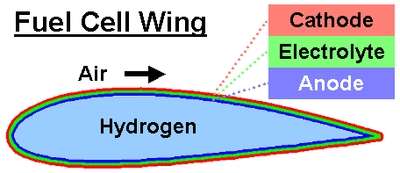

A fuel cell consists of two

electrodes sandwiched around an electrolyte. Hydrogen fed to the

one electrode (anode) passes through the electrolyte in the form of

protons and combines with oxygen on the other electrode (cathode)

making water and producing heat. Electricity is generated in the

process. A fuel cell will produce energy in the form of electricity

and heat as long as fuel and oxygen are supplied. To produce

fuel-cell quality hydrogen, an important step involves the removal

of any by-product carbon monoxide, which poisons the fuel cell

anode catalyst.

"A lot of people have spent a lot of time studying the

properties of gold and platinum nanoparticles that are used to

catalyze the reaction of carbon monoxide with water to make

hydrogen and carbon dioxide," said Maria Flytzani-Stephanopoulos,

professor of chemical and biological engineering at Tufts and the

lead researcher of the project. "We find that for this reaction

over a cerium oxide catalyst carrying the gold or platinum, metal

nanoparticles are not important. Only a tiny amount of the precious

metal in non metallic form is needed to create the active catalyst.

Our finding will help researchers find a cost-effective way to

produce clean energy from fuel cells in the near future"

She and her two colleagues, doctoral student Qi Fu and research

professor Howard Saltsburg, were funded by a $300,000 three-year

grant from the National Science Foundation, and have filed a

provisional patent for their research. Their cutting-edge work in

catalytic fuel processing to generate hydrogen for fuel cell

applications is one of the major undertakings at Tufts' Science and

Technology Center at the University's Medford campus (MA).

The Tufts researchers' article is based on the "water-gas shift"

reaction they use to make hydrogen from water and carbon monoxide

over cerium oxide loaded with gold or platinum. Typically, a

loading of 1-10 weight percent of gold or other precious metals is

used to make an effective catalyst. But the Tufts team discovered

that, after stripping the gold with a cyanide solution, the

catalyst was just as active with a slight amount of the gold

remaining – one-tenth the normal amount used.

According to Flytzani-Stephanopoulos, "This finding is

significant because it shows that metallic nanoparticles are mere

'spectator species' for some reactions, such as the water-gas

shift. The phenomenon may be more general, since we show that it

also holds for platinum and may also hold true for other metals and

metal oxide supports, such as titanium and iron oxide."

She adds, "It opens the way for new catalyst designs so more

hydrogen can be produced with less precious metal. This can pave

the way for cost-effective clean energy production from fuel cells

in the near future."

Fuel cells currently are being used on a trial basis in some

buses, cars and even hotels, but they're expensive. It may take up

to 10 years until the technology is used in transportation and by

the general population. (Since the 1960s, one type of fuel cell has

powered NASA's spacecrafts.)

"We've raised the issue of now having to look back and see if

less precious metal may be used in other similar applications,"

said Saltsburg. There's much more to be done, and that's what makes

the research exciting."

Airborne 10.15.25: Phantom 3500 Confounds, Citation CJ3 Gen2 TC, True Blue Power

Airborne 10.15.25: Phantom 3500 Confounds, Citation CJ3 Gen2 TC, True Blue Power Updated: Gryder Arrested On Gun Charge, Cites Georgia Stand Your Ground Law

Updated: Gryder Arrested On Gun Charge, Cites Georgia Stand Your Ground Law Aero-News: Quote of the Day (10.18.25)

Aero-News: Quote of the Day (10.18.25) ANN's Daily Aero-Term (10.18.25): Final Approach Point

ANN's Daily Aero-Term (10.18.25): Final Approach Point Classic Aero-TV: Eyeing the Hawk

Classic Aero-TV: Eyeing the Hawk