Process Could Allow Satellites To Be Replenished In Orbit

NASA has successfully concluded a remotely controlled test of new technologies that would empower future space robots to transfer hazardous oxidizer – a type of propellant – into the tanks of satellites currently in orbit. Concurrently on the ground, NASA is incorporating results from this test and the Robotic Refueling Mission on the International Space Station to prepare for an upcoming ground-based test of a full-sized robotic servicer system that will perform tasks on a mock satellite client.

Collectively, these efforts are part of an ongoing and aggressive technology development campaign to equip robots and humans with the tools and capabilities needed for spacecraft maintenance and repair, the assembly of large space telescopes, and extended human exploration.

The Satellite Servicing Capabilities Office (SSCO) at NASA's Goddard Space Flight Center in Greenbelt, Md., checked another critical milestone off their list with the completion of their Remote Robotic Oxidizer Transfer Test (RROxiTT) in February 2014. "This is the first time that anyone has tested this type of technology, and we've proven that it works. It's ready for the next step to flight," says Frank Cepollina, veteran leader of the five servicing missions to the Hubble Space Telescope and the associate director of SSCO. "RROxiTT gives NASA, and the satellite community at large, confidence that advanced satellite refueling and maintenance technologies aren't a wild dream of the future," says Cepollina. "They're being built and tested today – and the capabilities that they can unlock can become a reality."

Since 2009, SSCO has been investigating human and robotic satellite servicing while developing the technologies necessary to bring on-orbit spacecraft inspection, repair, refueling, component replacement and assembly capabilities to space.

Taking lessons learned from the successful Robotic Refueling Mission, the SSCO team devised the ground-based RROxiTT to test how robots can transfer hazardous oxidizer, at flight-like pressures and flow rates, through the propellant valve and into the mock tank of a satellite. While this capability could be applied to spacecraft in multiple orbits, SSCO focused RROxiTT specifically on technologies that could help satellites traveling the busy space highway of geosynchronous Earth orbit, or GEO.

Located about 22,000 miles above Earth, this orbital path is home to more than 400 satellites, many of which beam communications, television and weather data to customers worldwide. By developing robotic capabilities to repair and refuel GEO satellites, NASA hopes to add precious years of functional life to satellites and expand options for operators who face unexpected emergencies, tougher economic demands and aging fleets. NASA also hopes that these new technologies will help boost the commercial satellite-servicing industry that is rapidly gaining momentum.

Besides aiding the GEO satellite community, a capability to fix and relocate "ailing" satellites also could help mitigate the growing orbital debris problem that threatens continued space operations, ultimately making space greener and more sustainable. RROxiTT tested a suite of new robotic technologies and procedures developed by the SSCO team at two collaborating centers, Goddard and Kennedy Space Center, FL.

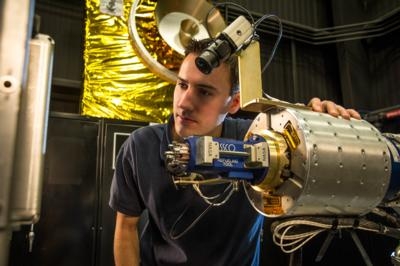

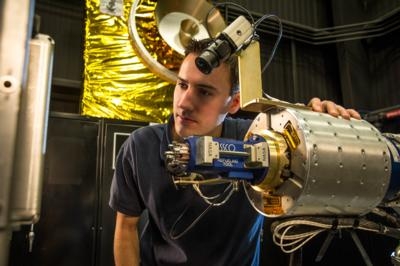

Technologies included a flexible propellant hose, a new Oxidizer Nozzle Tool, and a unique propellant transfer system (PTS) all developed by the multi-Center SSCO team. The PTS, consisting of oxidizer tanks, seal-less pumps, flow-metering devices, and a maze of tubing, contains the components a servicer satellite would need to replenish the propellant of orbiting spacecraft for many years of extended life.

During operations, a robot operator at NASA Goddard in Maryland commanded an industrial robot at Kennedy in Florida -- more than 800 miles away -- to mate to a satellite valve and transfer propellant into a mock tank. At the conclusion of nine days of RROxiTT operations, the SSCO team declared victory. "It's one thing to build a set of technologies and discover that they work," says Benjamin Reed, deputy project manager of SSCO at Goddard. "It's another thing to consider the capabilities that they could unlock. The paradigm of one-and-done should be relegated to the 20th century – the future of space will be re-use, re-purpose and replenish."

While RROxiTT technologies are being designed for use in space, they may one day be applied to robotically replenish satellites before they launch. Using these new RROxiTT technologies to robotically fill up satellites on the ground would keep humans at a safe distance during these extremely hazardous operations.

Since wrapping up RROxiTT, SSCO is broadening its portfolio to include xenon transfer technologies -- propellant used by satellites with electric propulsion systems. Upcoming demonstrations include spacecraft inspection, the replenishment of cryogens in satellites not originally designed for in-flight service, and advanced solar cell technology. A separate space station demonstration currently in development will focus on real-time relative navigation.

On the ground, SSCO will be conducting a separate test at Goddard in later this year. Drawing from lessons learned from RRM, RROxiTT, and their efforts in robot algorithms and development, the team will command a full-sized robot servicer system to perform a series of servicing tasks on a suspended satellite mockup. Results will help the team evaluate how the numerous servicer subsystems and technologies work together as an integrated system to accomplish servicing objectives. The event will test both proven and newly developed technologies.

"Sustainable space development is not only good stewardship of the shared resource of outer space," says Reed, "but it also makes sense as we develop the skill set to embark humans deeper into our solar system."

(Images provided by NASA. Top: RROxiTT lead roboticist Alex Janas stands with the Oxidizer Nozzle Tool as he examines the work site. Bottom: Artists concept of a robot servicer using autonomous rendezvous and fluid transfer technologies to extend the life of orbiting satellites)

ANN's Daily Aero-Term (05.29.25): Terminal Radar Service Area

ANN's Daily Aero-Term (05.29.25): Terminal Radar Service Area ANN's Daily Aero-Term (05.30.25): Very High Frequency (VHF)

ANN's Daily Aero-Term (05.30.25): Very High Frequency (VHF) Aero-News: Quote of the Day (05.30.25)

Aero-News: Quote of the Day (05.30.25) Airborne 05.23.25: Global 8000, Qatar B747 Accepted, Aviation Merit Badge

Airborne 05.23.25: Global 8000, Qatar B747 Accepted, Aviation Merit Badge ANN's Daily Aero-Linx (05.30.25)

ANN's Daily Aero-Linx (05.30.25)