No Mechanical Problems Suspected

As ANN first reported a couple of weeks

ago (ANN, March 3, 2003:

C-182 Down In PA) Butler (PA) businessman told air

traffic controllers about a buildup of ice on the wings of his

Cessna 182. That was just moments before he impacted the

ground and was killed last month, according to a preliminary report

of the accident from the NTSB.

As ANN first reported a couple of weeks

ago (ANN, March 3, 2003:

C-182 Down In PA) Butler (PA) businessman told air

traffic controllers about a buildup of ice on the wings of his

Cessna 182. That was just moments before he impacted the

ground and was killed last month, according to a preliminary report

of the accident from the NTSB.

David Howard, 50, of Butler, was on his way home from

Philadelphia Feb. 27 when he requested to land at the Butler County

Airport. He never arrived. His C-182 was found in a field about 20

miles north of Pittsburgh the next morning.

According to the NTSB report, Howard radioed air traffic

controllers telling them he noticed ice building up on his control

surfaces.

Fragments of ice shaped like the plane's wings and tail surfaces

were found near the wreckage.

The NTSB report said Howard did not mention any mechanical

problems with the aircraft before he impacted the ground. An

initial inspection of the engine showed no problems.

NTSB Preliminary Report

NTSB Identification: NYC03FA058

14 CFR Part 91: General Aviation

Accident occurred Thursday, February 27, 2003 in Renfrew

(PA)

Aircraft: Cessna 182G, registration: N3404S

Injuries: 1 Fatal.

This is preliminary information, subject to change, and may

contain errors. Any errors in this report will be corrected when

the final report has been completed.

HISTORY OF FLIGHT

On February 27, 2003, about 2135 eastern standard time, a Cessna

182G, N3404S, was substantially damaged when it impacted terrain

near Renfrew, Pennsylvania, while executing a visual approach to

runway 8 at the Butler County Airport (BTP), Butler, Pennsylvania.

The certificated private pilot was fatally injured. Night visual

meteorological conditions prevailed for the business flight that

departed Philadelphia International Airport (PHL), Philadelphia,

Pennsylvania, destined for Butler. An instrument flight rules (IFR)

flight plan was filed and activated for the flight conducted under

14 CFR Part 91.

According to air traffic control (ATC) data, the pilot reported

accumulating a significant amount of ice while en route to Butler.

Once in the Butler area, he advised the controller he had the

airport in sight, and the controller cleared him for the visual

approach to runway 8. No report of mechanical problems was received

from the pilot before the accident. When the airplane failed to

arrive at Butler, it was listed as missing, and search and rescue

operations were initiated.

According to a witness that was

approximately 1.2 miles northwest of the accident site, the

airplane was "very low," and descending rapidly while making a

180-degree turn. He reported that the airplane appeared to be

stable and that the landing light was on. He could not recall if he

heard any engine noise, but added that he was inside, and his

television was on. He did not witness the airplane impact the

ground.

According to a witness that was

approximately 1.2 miles northwest of the accident site, the

airplane was "very low," and descending rapidly while making a

180-degree turn. He reported that the airplane appeared to be

stable and that the landing light was on. He could not recall if he

heard any engine noise, but added that he was inside, and his

television was on. He did not witness the airplane impact the

ground.

According to another witness that was approximately 4oo feet

from the accident site, the airplane was very low, and unstable

when it flew by her bedroom window. The wings were rocking back and

forth, and she believes she heard the engine, but was not 100

percent sure. She did not witness the airplane impact the ground,

and was not aware of the accident until advised by local

authorities.

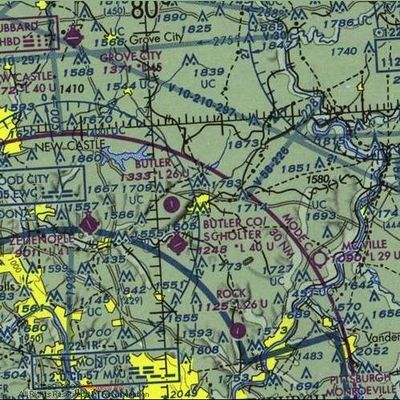

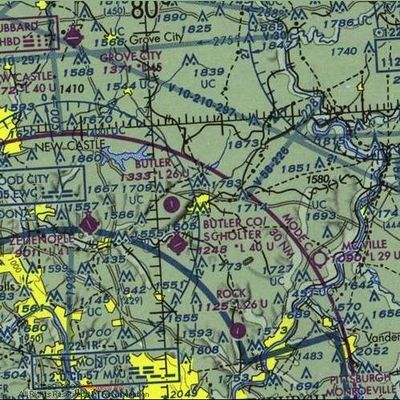

The accident occurred during the hours of darkness. The wreckage

was located at 40 degrees, 46.220 minutes north latitude, 79

degrees, 58.714 minutes west longitude, and an elevation of

approximately 1,160 feet msl.

PILOT INFORMATION

The pilot held a private pilot certificate with an airplane

single-engine-land rating, and airplane instrument rating. On his

last Federal Aviation Administration (FAA) third-class medical

certificate, dated April 23, 2002, he reported a total flight

experience of 466 hours.

METEOROLOGICAL INFORMATION

A weather observation taken at the time of the accident at the

Butler County Airport recorded the wind as 090 degrees at 5 knots,

visibility 10 miles, ceiling 3,700 feet overcast, temperature 30

degrees Fahrenheit, dew point 23 degrees Fahrenheit, and an

altimeter setting of 29.96 inches of mercury.

WRECKAGE AND IMPACT INFORMATION

The airplane impacted the ground about 1/2 mile from the

airport, and approximately 100 feet left of the extended centerline

for runway 8. Terrain in the area consisted of rolling hills,

farmland, and patches of forest. The debris path was approximately

50 feet long, orientated on a magnetic heading of 100 degrees, and

up slope approximately 5 degrees. The start of the debris path was

marked by freshly broken tree branches at the top of a 15-foot

tree. The debris path then consisted of one continues ground scar,

miscellaneous airframe components, and the main wreckage. All the

structural components of the airplane were accounted for at the

accident site. In addition, ice fragments were located at and near

the main wreckage. The fragments were approximately 2 inches thick

and 4.5 inches high. The color of the fragments was clear to

opaque, and the shapes were consistent with wing and tailplane

surfaces.

On February 28, 2003, the wreckage was moved to the Butler

County Airport, and placed in a secure hangar. On March 1, 2003,

the engine and airframe were examined.

Examination of the cockpit revealed that the airplane was not

equipped with shoulder harnesses. The seat tracks were bent and

broken, and the breaks matched the curvature of the floor. The

right seat was intact, the left seat had separated from the floor,

and the cushion along with its associated structure had separated

from the seat at all four of its connecting points. All four

fracture surfaces were gray in color and consistent with

overload.

Flight control continuity was confirmed from both ailerons to

both control yokes. Continuity of the elevator was confirmed from

the elevator to the base of the instrument panel, but not to the

control yokes because of impact damage. Rudder control continuity

was confirmed from the rudder to the forward part of the cockpit,

but not to the actual pedals because of impact damage. Elevator

trim was approximately neutral, and continuity was confirmed. The

flap switch was in the neutral position, the flap indicator showed

up, and the flaps were in the "UP" position.

The airspeed indicator displayed zero, and the vertical speed

indicator displayed 350 FPM down. The pilot altimeter indicated

7,560 feet and was set to 29.95 inches of mercury. The copilot

altimeter indicated 7,150 feet and was set to 29.95 inches of

mercury. The alternate static air was closed, and the pitot heat

was "ON." The attitude indicator displayed nose high and

approximately 45 degrees left wing low, the turn and bank indicator

displayed right wing low, and the ball was free in the race. The

No. 1 course deviation indicator (CDI) was set to 266 degrees,

showed on course, and full deflection below glideslope. The No. 2

CDI was set to 254 degrees, indicated three dots right of course,

and full deflection above glideslope. The directional gyro

indicated 231 degrees, and the magnetic compass indicated 221

degrees. The ADF needle indicated 225 degrees, and the card was set

to 035 degrees. In addition, no indication of "needle slap" was

identified on any of the flight or navigation instruments.

The ICS control panel was configured with speaker and headphone

for the No. 1 communication radio, nothing for the No. 2

communication radio, and nothing for the No. 1 navigation radio.

Speaker and headphone were selected for the No. 2 navigation radio,

and headphone was selected for the DME. Speaker and headphone were

selected for the marker beacon, and speaker was selected for the

ADF. In addition, the transmit selector was set to the No. 1

communication radio.

The No. 1 and No. 2 communication radios were "ON," and the

volumes were mid range. The No. 1 and No. 2 navigation radios were

"ON" and the volumes were approximately maximum. The ADF was "ON,"

the volume was mid range, and "ADF" was selected. The transponder

was set to 2672, and the selector switch had separated from the

unit.

The No. 1 and No. 2 communication radios, the No. 1 and No. 2

navigation radios, the Loran "C," and the ADF all had electronic

displays. The airplane battery was reinstalled, and the master

switch along with the avionics switch, were placed in the "ON"

position. All the avionics displayed indications of power, but only

the following data could be extracted. The No. 1 communication

radio was set to 124.75 MHz active and 122.8 MHz standby. The No. 2

communication radio was set to 133.82 MHz active and 122.8 MHz

standby. The No. 1 Navigation radio was set to 113.0 MHz active,

and 112.5 MHz standby.

The engine oil pressure gauge indicated zero, the engine oil

temperature gauge indicated zero, and the vacuum gauge indicated

zero. The manifold pressure gauge indicated 29 inches of mercury,

and the tachometer indicated zero RPM and 784.66 hours. The clock,

which was powered by the airplane battery indicated 2050. In

addition, no indication of "needle slap" was identified on any of

the system instruments or clock.

The fuel selector displayed impact damage, and the handle was

between "BOTH" and "OFF." The selector was opened and the valve was

in the "BOTH" position. The throttle was full forward, the mixture

was full "RICH," and the propeller control was approximately 1/2

inch aft of full forward. The carburetor heat was full forward. The

primer was in and locked. The master switch was "OFF," and magnetos

were set to "BOTH."

The propeller had separated from the engine and both blades were

attached to the propeller hub. The No. 1 blade displayed chordwise

scratches and "S" bends. The No. 2 blade was rolled back, displayed

"S" bends and chordwise scratches.

The engine case displayed minimal impact damage except for an

impact mark below the propeller flange. Continuity of the induction

and exhaust system could not be confirmed because of impact damage.

All six top sparkplugs were removed. The No. 1, 2, 4, and 6,

sparkplugs were gray in color and absent of debris. The No. 3, and

5 sparkplugs were oil soaked and absent of debris. A rotational

force was applied to the engine crankshaft, compression was

obtained on all six cylinders, valve train continuity was

confirmed, and all the top ignition leads produced spark.

Engine control continuity was confirmed from the cockpit to the

carburetor for the throttle and mixture controls, and from the

cockpit to the propeller governor for the propeller control.

Continuity of the carburetor heat control to the carburetor heat

box was confirmed, but the position of the carburetor heat valve

could not be determined because of impact damage. The throttle

valve was in the closed position. The mixture control arm had

separated from the carburetor, and the mixture control shaft was in

the full rich position.

The carburetor displayed impact damage. The fuel line from the

carburetor was removed and approximately 1.0 ounce of residual fuel

was captured. The fuel was bluish in color and absent of

contaminates. The fuel screen was removed, and absent of debris.

About 1.5 ounces of fuel was drained from the carburetor bowl. It

was bluish in color and absent of contaminates. The carburetor was

then opened, and another 0.5 ounce of fuel was drained. The fuel

was absent of debris, and had a purple tent to it. The float

assembly, needle valve, and accelerator pump were intact.

The vacuum pump was removed, the shear coupling was intact, and

the pump rotated freely. The pump was then opened. The rotor was

intact, along with all of the vanes.

The attitude indicator was removed from the instrument panel,

and the vertical gyro housing was opened. The rotor housing and

housing cover displayed a rotational scar. No rotational scarring

was identified on the rotor itself.

The carburetor ice indicator light was removed from the

instrument panel and examined. The filament was broken, displayed

no elongation, and the fracture surfaces were consistent with a

cold break.

Examination of the airplane battery revealed it was in good

condition, and capable of generating 11.17 volts. It was

reinstalled in the airplane, and no reduction in battery

performance was noted after approximately 30 minutes of having the

majority of the avionics in the "ON position and consuming

power.

ADDITIONAL INFORMATION

The wreckage was released to the owner's representative on March

1, 2003.

Affordable Flying Expo Announces Industry MOSAIC Town Hall

Affordable Flying Expo Announces Industry MOSAIC Town Hall Classic Aero-TV: Composite-FX Sets Elevates the Personal Helicopter Market

Classic Aero-TV: Composite-FX Sets Elevates the Personal Helicopter Market Aero-News: Quote of the Day (10.25.25)

Aero-News: Quote of the Day (10.25.25) ANN's Daily Aero-Term (10.25.25): Ground Stop (GS)

ANN's Daily Aero-Term (10.25.25): Ground Stop (GS) NTSB Final Report: Gallow Daniel A Kitfox Classic IV

NTSB Final Report: Gallow Daniel A Kitfox Classic IV