Tue, Jul 05, 2011

Accuracies Of Less Than One-Millionth Of An Inch Required

Mirrors are a critical part of a telescope. The quality is

crucial, so completion of mirror polishing represents a major

milestone. All of the mirrors that will fly aboard NASA's James

Webb Space Telescope have been polished so the observatory can see

objects as far away as the first galaxies in the universe.

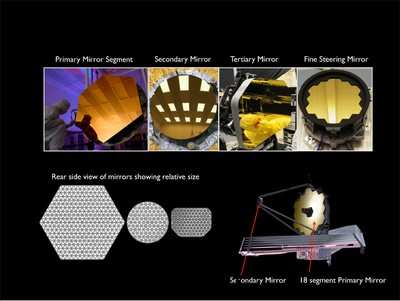

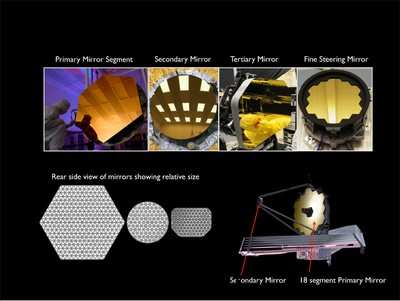

The Webb telescope is comprised of four types of mirrors. The

primary one has an area of approximately 29.9 square yards, which

will enable scientists to capture light from faint, distant objects

in the universe faster than any previous space observatory. The

mirrors are made of Beryllium and will work together to relay

images of the sky to the telescope's science cameras. "Webb's

mirror polishing always was considered the most challenging and

important technological milestone in the manufacture of the

telescope, so this is a hugely significant accomplishment," said

Lee Feinberg, Webb Optical Telescope manager at NASA's Goddard

Space Flight Center in Greenbelt, MD.

The mirrors were polished at the L3 Integrated Optical Systems -

Tinsley in Richmond, CA. to accuracies of less than one millionth

of an inch. That accuracy is important for forming the sharpest

images when the mirrors cool to -400 degrees F (-240 degrees C) in

the cold of space. "The completion of the mirror polishing shows

that the strategy of doing the hardest things first has really paid

off," said Nobel Prize Winner John C. Mather, Webb's senior project

scientist at Goddard. "Some astronomers doubted we could make these

mirrors."

After polishing, the mirrors are being coated with a

microscopically thin layer of gold to enable them to efficiently

reflect infrared light.

NASA has completed coating 13 of 18 primary mirror segments and

will complete the rest by early next year. The 18 segments fit

together to make one large mirror 21.3 feet across. "This milestone

is the culmination of a decade-long process," said Scott

Willoughby, vice president and Webb Telescope Program manager for

Northrop Grumman Aerospace Systems. "We had to invent an entire new

mirror technology to give Webb the ability to see back in

time."

More News

Have A Story That NEEDS To Be Featured On Aero-News? Here’s How To Submit A Story To Our Team Some of the greatest new stories ANN has ever covered have been submitted by our>[...]

“The legislation now includes a task force with industry representation ensuring that we have a seat at the table and our voice will be heard as conversations about the futur>[...]

Aero Linx: Waco Museum The WACO Historical Society, in addition to preserving aviation's past, is also dedicated and actively works to nurture aviation's future through its Learnin>[...]

Adcock Range National low-frequency radio navigation system (c.1930-c.1950) replaced by an omnirange (VOR) system. It consisted of four segmented quadrants broadcasting Morse Code >[...]

Also: uAvionix AV-Link, Does Simming Make Better Pilots?, World Games, AMA National Fun Fly Czech sportplane manufacturer Direct Fly has finished delivering its 200th ALTO NG, the >[...]

ANN FAQ: Submit a News Story!

ANN FAQ: Submit a News Story! Aero-News: Quote of the Day (06.12.24)

Aero-News: Quote of the Day (06.12.24) ANN's Daily Aero-Linx (06.12.24)

ANN's Daily Aero-Linx (06.12.24) ANN's Daily Aero-Term (06.12.24): Adcock Range

ANN's Daily Aero-Term (06.12.24): Adcock Range Airborne Affordable Flyers 06.06.24: 200th ALTO, Rotax SB, Risen 916iSV

Airborne Affordable Flyers 06.06.24: 200th ALTO, Rotax SB, Risen 916iSV