Wed, Jun 24, 2009

New Propulsion System Will Keep 'Space Habitat' Aloft Using

Common Gasses

Orion Propulsion, Inc.

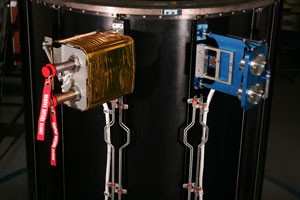

Tuesday announced completion of a qualification test program for

the Forward Propulsion System (FPS) of Bigelow Aerospace’s

Sundancer Project, the world’s first commercial space

habitat. The Orion Propulsion thruster system uses hydrogen and

oxygen that are produced from Bigelow’s proprietary

Environmental Control Life Support System (ECLSS) as propellants

for the spacecraft’s attitude control system. This truly

“people-powered” space craft, which burns hydrogen and

oxygen generated from water, sweat, and urine, eliminates the need

for more toxic propellants such as hydrazine and nitrogen tetroxide

that are more costly to use and harmful to the environment - on

Earth and in space.

Orion Propulsion, Inc.

Tuesday announced completion of a qualification test program for

the Forward Propulsion System (FPS) of Bigelow Aerospace’s

Sundancer Project, the world’s first commercial space

habitat. The Orion Propulsion thruster system uses hydrogen and

oxygen that are produced from Bigelow’s proprietary

Environmental Control Life Support System (ECLSS) as propellants

for the spacecraft’s attitude control system. This truly

“people-powered” space craft, which burns hydrogen and

oxygen generated from water, sweat, and urine, eliminates the need

for more toxic propellants such as hydrazine and nitrogen tetroxide

that are more costly to use and harmful to the environment - on

Earth and in space.

Tim Pickens, CEO of Orion Propulsion, said, “We are

excited to complete this critical demonstration that will move

Bigelow Aerospace one step closer to creating a

self–sufficient commercial human habitat that is safer and

more environmentally friendly than any other system in use. I am

proud of our team for delivering a best-in-class solution for this

landmark project. We look forward to completing production and

flying critical flight hardware on the world’s first

commercial space habitat.”

“Orion Propulsion has been an excellent partner and has

met every delivery date and performance milestone,” said

Bigelow Aerospace Program Manager, Eric Haakonstad. “Their

team worked with our very specific and demanding requirements to

put together an elegant and “green” propulsion system

that is safe, cost efficient, powerful and reliable - these are

critical elements that will enable Sundancer’s success over

its 15 year life cycle in space.”

The test program was a thorough evaluation of the propulsion

system and included thermal cycle vacuum testing, electro-magnetic

interference testing, acoustic and vibration testing. In addition,

an accelerated life test program was conducted simulating space

environments including vacuum, and temperature swings. The

culmination of the qualification period was a Design Certification

Review held with Bigelow Aerospace May 27-28, 2009. The review

presented the results of the qualification test program and

documented the requirement verification process for the FPS. The

review was passed and authority has been given to proceed with

assembly of the flight hardware. The assembly of flight hardware

began June 1, 2009 and will continue through the summer. The first

flight ship-set should be completed in August of this year.

The Orion Propulsion “green propulsion” system

provides environmental benefits through eliminating the need to

launch into the atmosphere other highly toxic propellants such as

hydrazine or nitrogen tetroxide, thus reducing weight and launch

costs. It also creates a safer, cleaner work environment for humans

on Earth and in space. In addition, it can be adapted for other

uses including “roll control” for small launch vehicles

and propulsion or attitude control on other space craft.

More News

Circle To Runway (Runway Number) Used by ATC to inform the pilot that he/she must circle to land because the runway in use is other than the runway aligned with the instrument appr>[...]

Aero Linx: National Aviation Safety Foundation (NASF) The National Aviation Safety Foundation is a support group whose objective is to enhance aviation safety through educational p>[...]

At Altitude Of About 250-300 Ft Agl, The Airplane Experienced A Total Loss Of Engine Power On November 6, 2024, at 1600 central standard time, a De Havilland DHC-1, N420TD, was inv>[...]

From 2009 (YouTube Edition): Three Hour Flight Was 'Flawless' -- At Least, Until Mother Nature Intervened For anyone who loves the aviation business, this was a VERY good day. Afte>[...]

Also: AMA Names Tyler Dobbs, More Falcon 9 Ops, Firefly Launch Unsuccessful, Autonomous F-16s The Air Force has begun ground testing a future uncrewed jet design in a milestone tow>[...]

ANN's Daily Aero-Term (05.05.25): Circle To Runway (Runway Number)

ANN's Daily Aero-Term (05.05.25): Circle To Runway (Runway Number) ANN's Daily Aero-Linx (05.05.25)

ANN's Daily Aero-Linx (05.05.25) NTSB Prelim: De Havilland DHC-1

NTSB Prelim: De Havilland DHC-1 Classic Aero-TV: The Boeing Dreamliner -- Historic First Flight Coverage

Classic Aero-TV: The Boeing Dreamliner -- Historic First Flight Coverage Airborne-NextGen 05.06.25: AF Uncrewed Fighters, Drones v Planes, Joby Crew Test

Airborne-NextGen 05.06.25: AF Uncrewed Fighters, Drones v Planes, Joby Crew Test