CST-100 Spacecraft To Be Manufactured And Operated At Kennedy

Space Center

Boeing plans to consolidate its Commercial Crew program office,

manufacturing and operations at the Kennedy Space Center (KSC), the

company announced Monday. Boeing, in partnership with Space

Florida, has an arrangement to use the Orbiter Processing

Facility-3 (OPF-3) to manufacture, assemble, and test the

company’s Crew Space Transportation (CST)-100 spacecraft.

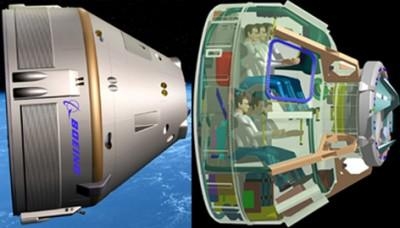

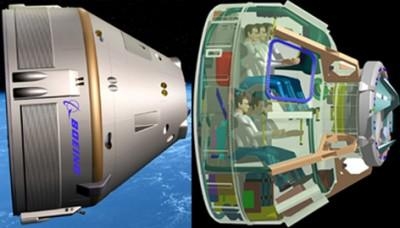

CST-100 Boeing Image

"We selected Florida due to the cost benefits achieved with a

consolidated operation, the skilled local workforce, and proximity

to our NASA customer,” said John Mulholland, vice president

and program manager of Commercial Programs for Boeing Space

Exploration. “Pending the continued selection of Boeing for

future Commercial Crew development and service contracts, and

sufficient NASA funding, we project a Commercial Crew program

workforce ramping up to 550 local jobs by our scheduled operational

date of December 2015. The CST-100 will provide NASA with reliable,

safe, and affordable transportation to the International Space

Station and other destinations in Low Earth Orbit.”

"We are extremely pleased that Boeing will locate its Commercial

Crew headquarters here in Florida," said Frank DiBello, president

of Space Florida, the State’s aerospace economic development

agency. "This positions our state well for future growth and a

leadership role in NASA's next generation human space exploration

initiatives. It is also a key factor in ensuring Florida's

space-related economy continues to thrive after shuttle

retirement."

Frank DiBello

Boeing is working with Space Florida on agreements to use

Kennedy Space Center’s Orbiter Processing Facility Bay 3

(OPF-3) and Processing Control Center (PCC) facilities for

Commercial Crew program execution. The OPF-3, previously used to

perform maintenance on the space shuttle orbiters, features

approximately 64,000 square feet of manufacturing and processing

areas and about 64,000 square feet of office, laboratory and

logistics areas. The PCC consists of approximately 99,000 square

feet of control rooms and office space Boeing plans to use to

support mission operations, training and program offices. The PCC

previously supported shuttle orbiter testing, launch team training,

and computer system software and hardware development and

maintenance operations.

In partnership with Space Florida, Boeing plans to modernize the

facilities to provide efficient production and testing operations

that optimize the company’s best practices from satellite

manufacturing, space launch vehicles and commercial airplane

production programs.

The Commercial Crew program consists of developing,

manufacturing, testing and evaluating, and demonstrating the

CST-100 spacecraft, launch vehicle and mission operations -- all

part of Boeing’s Commercial Crew Transportation System (CCTS)

-- for NASA’s new Commercial Crew human spaceflight program

that will provide flights to the International Space Station.

Boeing’s system will also be capable of supporting Bigelow

Aerospace’s planned orbital space complex. The program is

based on the company’s experience and innovation over the

past 50 years of human spaceflight and nearly 100 years of

commercial aviation.

The CST-100 is a reusable capsule-shaped spacecraft based on

proven materials and subsystem technologies that can transport up

to seven people, or a combination of people and cargo. Boeing has

designed the spacecraft to be compatible with a variety of

expendable rockets and selected the United Launch Alliance’s

Atlas V launch vehicle for initial CST-100 test flights in

2015.

In his remarks, Mulholland expressed Boeing’s gratitude to

the organizations that contributed to the success of this project,

including NASA, Space Florida, Economic Development Commission of

Florida’s Space Coast, Enterprise Florida, the Brevard County

Board of County Commissioners, and Brevard Workforce.

ANN's Daily Aero-Term (12.14.25): Local Airport Advisory (LAA)

ANN's Daily Aero-Term (12.14.25): Local Airport Advisory (LAA) Airborne 12.08.25: Samaritans Purse Hijack, FAA Med Relief, China Rocket Fail

Airborne 12.08.25: Samaritans Purse Hijack, FAA Med Relief, China Rocket Fail ANN's Daily Aero-Linx (12.15.25)

ANN's Daily Aero-Linx (12.15.25) Airborne 12.10.25: New Gulfstream, ATC Integrator, Outrageous FFZ User Fees

Airborne 12.10.25: New Gulfstream, ATC Integrator, Outrageous FFZ User Fees Airborne-NextGen 12.09.25: Amazon Crash, China Rocket Accident, UAV Black Hawk

Airborne-NextGen 12.09.25: Amazon Crash, China Rocket Accident, UAV Black Hawk