Sat, Jun 10, 2023

McFarlane Acquires Airforms

Founded in 1971, Baldwin City, Kansas-based McFarlane is a diversified manufacturing company specializing in the production of affordable, high-quality FAA-PMA (Parts Manufacture Approval) components. McFarlane’s catalog comprises parts for general aviation, commercial, experimental, homebuilt, and Light-Sport Aircraft (LSA) models.

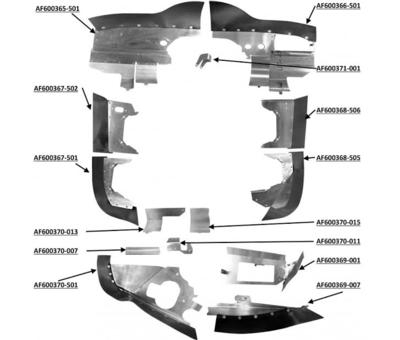

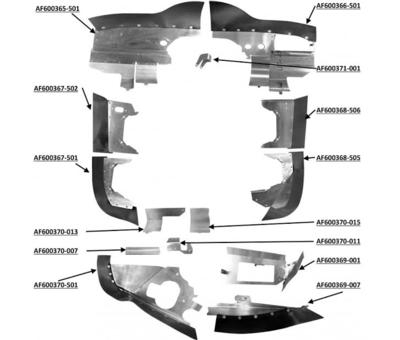

On 07 June 2023, McFarlane subsidiary Airforms introduced a new series of FAA-PMA engine baffles compatible with all Cessna-152 OEM configurations.

Designed as replacements for aging factory installations, Airforms’s new baffles have undergone individual PMA approval and may be purchased as standalone units or as a complete set. The product’s reinforced design ensures extended durability and reduces metal fatigue failures. What’s more, Airforms’s baffle assemblies are offered in both a bare metal and a corrosion-resistant powder-coated finish. Standard silicone seals and low friction COWL SAVER seals are available as options.

Airforms’s manufacturing operations are based at the company’s Wasilla, Alaska Airforms Center for Engine Baffle Excellence.

Baffles are essential to the business of routing cooling air around air-cooled aero-engines—such as the Lycoming O-235-L2C powerplant common to Cessna’s storied 152 aircraft family. Broadly speaking, air-cooled general aviation engines are cooled primarily by a process known as pressure cooling—the rudiments of which constitute surrounding the engine with a cowling and utilizing a system of baffles to seal and direct ram-air around the powerplant. The described architecture occasions high-pressure (relative to ambient atmospheric pressure) which forces air to flow between the heat-radiating fins typical of the cylinder-assemblies of air-cooled engines. Many higher-performance aircraft designs make use of cowl-flaps which, when opened by the pilot, reduce air-pressure below the engine, thereby inducing greater air-flow (high-pressure to low-pressure) through such.

McFarlane holds design approval and FAA-PMA for over 2,700 discrete replacement parts for numerous aircraft makes.

More News

From 2023 (YouTube Edition): "Ain’t Your Daddy’s Super Cub”—Don Wade Co-owned by Don and Ron Wade—the former of Don’s Dream Machines, a storied >[...]

Pilot-Rated Passenger Reported That The Pilot Did Not Adequately “Round Out” The Landing Flare And The Airplane Bounced And Yawed To The Right Analysis: The pilot state>[...]

Dead Reckoning Dead reckoning, as applied to flying, is the navigation of an airplane solely by means of computations based on airspeed, course, heading, wind direction, and speed,>[...]

Aero Linx: Lake Amphibian Club This website is created and sponsored by the Lake Amphibian Club, to help spread the word about these wonderful, versatile amphibians that can land j>[...]

“I am deeply honored to be sworn in as NASA administrator. NASA’s mission is as imperative and urgent as ever — to push the boundaries of human exploration, ignit>[...]

Classic Aero-TV: In Praise of Alabamas Patriot Aircraft USA

Classic Aero-TV: In Praise of Alabamas Patriot Aircraft USA NTSB Final Report: Cirrus Design Corp SR22

NTSB Final Report: Cirrus Design Corp SR22 ANN's Daily Aero-Term (12.21.25): Dead Reckoning

ANN's Daily Aero-Term (12.21.25): Dead Reckoning ANN's Daily Aero-Linx (12.21.25)

ANN's Daily Aero-Linx (12.21.25) Aero-News: Quote of the Day (12.21.25)

Aero-News: Quote of the Day (12.21.25)