Honda's BizJet Entry Moving Quietly Along

It's anywhere from a year to four or more, behind its direct

competion, but Honda's business jet is nearly ready for its first

test flight, which is expected later this year.

The machine was designed around two major parameters: efficiency

(fuel consumption and range at various loads) and a large cabin,

with the latter's being the most important of all.

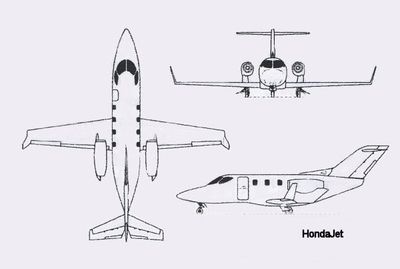

Big on the inside, unusual on the outside:

Focus groups in major US cities told Honda that the interior

space was a huge consideration, so huge, in fact, that Honda's

design is, well, a little weird. In order to get the interior cube

as big as possible and still have enough efficiency to cruise its

anticipated 389 knots, the 1670-pound-thrust (at takeoff)

Honda-built HF-118 engines are mounted on pylons... on top of the

wings.

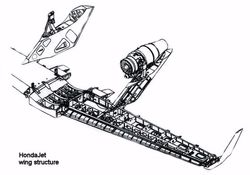

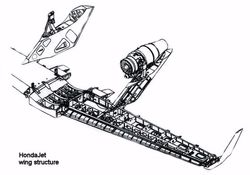

The three-spar metal wing structure, nearly 40 feet across,

passing below the cabin, and ending in small winglets, has extra

reinforcement where the pylons attach. On the bottom of the wings,

at the same point, you'll find the main gear attachments. Gear, we

hear, is being developed for Honda by Sumitomo.

Wing anti-icing is to be supplied by a bleed air system.

Four fuel tanks (one in each wing, one central tank, and one at

the rear) are all fed from a single inlet at the right rear of the

machine; transfer pumps manage fuel loading and in-flight balance.

Honda isn't saying just how much fuel the machine will carry, but

its 9200lb target MTOW and 1100nm IFR range give those who have a

clue, a couple more clues.

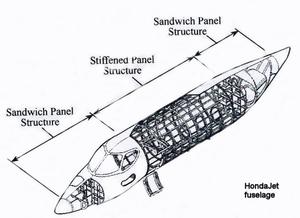

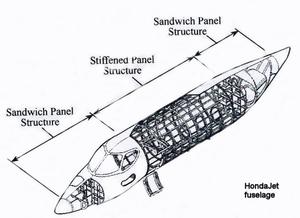

A truly 'composite construction' airplane: metal wing, graphite

fuselage.

With standard seating for

six, including two crew and a lavatory, the HondaJet can actually

be configured for eight (no lav), in a cabin that's about 4'10"

high, at the center of the aisle. The composite fuselage is

designed so that the center section can be "stretched," if Honda

wants to turn its BJ into a baby RJ.

With standard seating for

six, including two crew and a lavatory, the HondaJet can actually

be configured for eight (no lav), in a cabin that's about 4'10"

high, at the center of the aisle. The composite fuselage is

designed so that the center section can be "stretched," if Honda

wants to turn its BJ into a baby RJ.

The nose and tail are a "sandwich panel" construction, while the

main cabin is a "stiffened panel" structure. Honda is proud of the

challenge it overcame to autoclave the whole thing at once -- it's

hard to not crush the honeycomb, while still getting the 85psi that

the stiffened-panel nose and tail require.

The pressurization, 8.7psi, gives the 8000-foot cabin a max

altitude of 44,000 feet, with best cruise at 41,000, and the

engineered maximum speed of 420 knots down at 30,000.

Laminar flow requirements led to a whole new airfoil.

Honda developed its own airfoil for the HondaJet, and has tested

it on a T-33, as well as in wind tunnel models of various sizes.

The SHM-1 airfoil, the company says, "...exhibits a high maximum

lift coefficient with docile stall characteristics in cruise and

climb." The wing, with its flap system, has received extensive

testing, and seems to safely carry the airplane through all

anticipated speed/AOA combinations; and to be recoverable from even

intentional deep stalls.

Putting the engines atop the wings, though, provided some

engineering "opportunities." Honda's development team

acknowledges that, "locating the engine nacelles over the wing

causes unfavorable aerodynamic interference and induces a

strong shock wave." Interior capacity, though, forced Honda's

engineers to figure out how to get around that problem. They say

the solution, examined in their own low-speed wind tunnel and in

Boeing's transsonic tunnel, yields stall and flutter numbers that

are quite acceptable; some are virtually indistinguishable from

those generated by the "clean" wing.

Flaps will be set to 15.7 degrees for takeoff, and up to 50

degrees for landing. The nose wheel steers -- 10 degrees left and

right in "takeoff" mode, and 50 to a side in "taxi," for a tight

low-speed turning radius.

The nose and tail received a lot of attention, as well, and

Honda believes its nose is close to an ideal laminar-flow example,

for the speeds where the airplane will operate. The tail end of the

fuselage, always aerodynamically compromised by the need to rotate

and flare, itself demanded a lot of the aerodynamicists' time.

The machine's T-tail, another potential flutter center, has also

been modeled and then tested in both low-speed and transsonic wind

tunnels, with various loading simulating control deflection, angle

of attack, and yaw.

Up front, the cockpit will have a full Garmin panel, with a big

MFD in the center, flanked by two PFDs. The displays themselves are

interchangable.

So far, Honda has built the major structures, and has done a lot

to try to destroy them, as well. Ground function tests have

started. Ultimate loads have not been tested, Honda said, because

the machine whose components they're torturing will become the

first flying prototype. No availability date or pricing information

are available.

Airborne 10.14.25: Laser Threat, VeriJet BK, Duffy Threatens Problem Controllers

Airborne 10.14.25: Laser Threat, VeriJet BK, Duffy Threatens Problem Controllers Airborne 10.15.25: Phantom 3500 Confounds, Citation CJ3 Gen2 TC, True Blue Power

Airborne 10.15.25: Phantom 3500 Confounds, Citation CJ3 Gen2 TC, True Blue Power Aero-News: Quote of the Day (10.17.25)

Aero-News: Quote of the Day (10.17.25) NTSB Prelim: Piper PA-28-180

NTSB Prelim: Piper PA-28-180 ANN FAQ: Contributing To Aero-TV

ANN FAQ: Contributing To Aero-TV