Wed, Oct 26, 2022

Identifies Possible Safety Issue in Tragic Mutiny Bay Accident

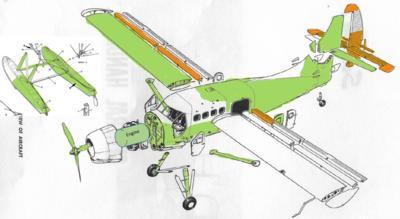

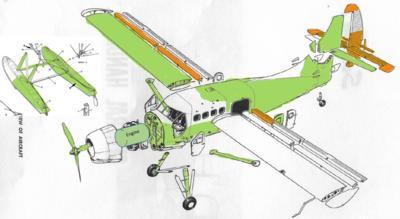

National Transportation Safety Board investigators identified a possible safety issue with a flight control of the De Havilland Canada DHC-3 that crashed into Mutiny Bay, Washington on Sept. 4, 2022. Tragically, the pilot and nine passengers were fatally injured.

Investigators found (recovered airframe parts shown in green) the horizontal stabilizer actuator, which is part of the airplane’s pitch trim control system and is also referred to as the trim jack, had separated into two pieces. The actuator was found separated where the clamp nut threads into the barrel section. Examination of the threads inside the barrel and the threads on the clamp nut revealed that the two components separated by unthreading as opposed to being pulled apart in tension. A circular wire lock ring is used to prevent the barrel and clamp nut from unthreading. The lock ring was not yet located in the wreckage. This possible safety issue could result in a possible loss of airplane control.

At this time, the NTSB does not know whether the lock ring was installed before the airplane impacted the water or why the lock ring was not present during the airplane examination.

The NTSB, in coordination with the Transportation Safety Board of Canada, has asked that the manufacturer draft instructions for an inspection of the actuator to ensure that the lock ring is in place and properly engaged to prevent unthreading of the clamp nut. Those instructions will be released and provided to all operators of the DHC-3 airplane worldwide in a Service Letter.

The investigation into this accident will continue with examinations of both elevators in the NTSB Materials Laboratory; interviews of the FAA principal operations and principal maintenance inspectors assigned to the operator; a review of maintenance records, including historical records for accidents, incidents and service difficulty reports and interviews with maintenance personnel. An evaluation of lock ring failure modes and lock ring installation instructions will be accomplished in addition to an aircraft performance study.

The wreckage recovery operation was completed on September 30 with approximately 85% of the airplane recovered from the sea floor. A field examination of the wreckage occurred during the week of October 3, with follow-up activities in the NTSB Materials Laboratory in Washington, D.C. The horizontal stabilizer actuator and both elevators were shipped to the NTSB Materials Laboratory for further examination.

All aspects of the crash remain under investigation while the NTSB determines the probable cause, with the intent of issuing safety recommendations to prevent similar crashes. The information in the update is preliminary and subject to change as the investigation continues.

More News

Aero Linx: International Federation of Airworthiness (IFA) We aim to be the most internationally respected independent authority on the subject of Airworthiness. IFA uniquely combi>[...]

Ultrahigh Frequency (UHF) The frequency band between 300 and 3,000 MHz. The bank of radio frequencies used for military air/ground voice communications. In some instances this may >[...]

A Few Questions AND Answers To Help You Get MORE Out of ANN! 1) I forgot my password. How do I find it? 1) Easy... click here and give us your e-mail address--we'll send it to you >[...]

From 2019 (YouTube Edition): Learning To Paint Without Getting Any On Your Hands PPG's Aerospace Coatings Academy is a tool designed to teach everything one needs to know about all>[...]

Also: Sustainable Aircraft Test Put Aside, More Falcon 9 Ops, Wyoming ANG Rescue, Oreo Cookie Into Orbit Joby Aviation has reason to celebrate, recently completing its first full t>[...]

ANN's Daily Aero-Linx (05.06.25)

ANN's Daily Aero-Linx (05.06.25) ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF)

ANN's Daily Aero-Term (05.06.25): Ultrahigh Frequency (UHF) ANN FAQ: Q&A 101

ANN FAQ: Q&A 101 Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training

Classic Aero-TV: Virtual Reality Painting--PPG Leverages Technology for Training Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance

Airborne 05.02.25: Joby Crewed Milestone, Diamond Club, Canadian Pilot Insurance