Tue, Jul 20, 2004

New Generation High Performance Resin For Aerospace And

Commercial Applications

UBE America and NASA have entered

into a license agreement for NASA's PETI-330. The announcement was

made by representatives of NASA, UBE America and UBE Industries

during the recent SAMPE meeting in Long Beach (CA).

UBE America and NASA have entered

into a license agreement for NASA's PETI-330. The announcement was

made by representatives of NASA, UBE America and UBE Industries

during the recent SAMPE meeting in Long Beach (CA).

PETI-330 was developed at NASA-Langley by a team headed by John

W. Connell and is covered by US Patent No. 6,359,107, "Composition

of and method for making high performance resins for infusion and

transfer molding processes." PETI-330 offers cost effective and

affordable fabrication of high temperature composite structures for

advanced aerospace vehicles. The unique combination of high

temperature performance and processing characteristics enables new

applications.

PETI-330 will be marketed and sold in North America by UBE

America under the license from NASA.

PETI-330 offers the following innovative characteristics:

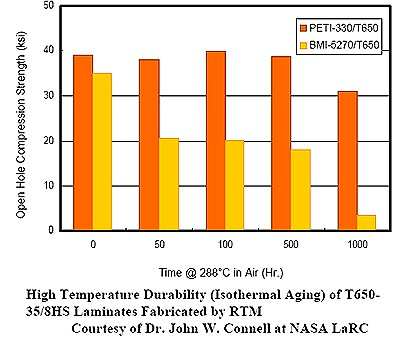

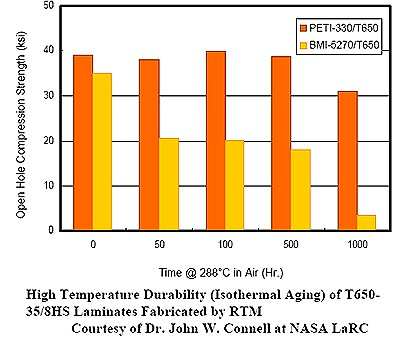

- PETI-330 composites have excellent long-term (1,000 hours)

performance at 300�C.

PETI-330 provides an unprecedented combination of easy processing

for composite fabrication together with high temperature

performance and toughness.

- PETI-330 offers low (<10 Pa-s, 288�C) and stable melt

viscosity highly suited to RTM and other resin infusion

processes.

- There is a simple and efficient 1-hour full cure process with

no post-cure required.

- It has a high glass transition temperature 330�C /

626�F

- PETI-330 is both solvent free (no volatiles) and non toxic

- These characteristics provide the following benefits:

- Substantial improvements in both high and low temperature

performance compared with traditional materials such as epoxies or

bismaleimides.

- Superior combination of processability and mechanical

properties compared with existing polyimides such as PMR-15

- A simplified cure process which makes it highly suitable for

mass production requirements

- A reduced fabrication time for components and assemblies

- Reduced mass & weight for high temperature structural

applications (i.e. it can replace metallic parts and

assemblies)

- A more cost effective alternative to complex part

assembly

A spokesman for UBE stated, "UBE Industries will fully support

the efforts of UBE America to develop and expand the market for

this revolutionary resin. UBE continues its research and

development work on new resins for aerospace applications."

"The first market to benefit from this new technology will be

the aerospace industry, particularly the military sector. PETI-330

will replace metal parts of the aircraft, including helicopters,

which will considerably decrease their weight," said Kei Tsukahara,

product manager, UBE America.

"We expect a great demand for this exciting new product. UBE

America is currently working on creating an inventory of samples

for potential customers," said Tsukahara.

UBE Industries has a patent on additional types of polyimide

using a-BPDA in the United States. It is currently filing for

patents in Europe and Japan.

PETI-330 complements the existing portfolio of products offered by

UBE for the aerospace industry, including UPILEX Polyimide Film and

TYRANNO Silicon Carbide Fiber.

More News

From 2014 (YouTube Version): One Of The Airshow World's Pre-Eminent Formation Teams Chats About The State Of The Industry At EAA AirVenture 2014, ANN News Editor Tom Patton gets th>[...]

Tactical Air Navigation (TACAN) An ultra-high frequency electronic rho-theta air navigation aid which provides suitably equipped aircraft a continuous indication of bearing and dis>[...]

Aero Linx: Doobert Hi, we're Chris & Rachael Roy, founders and owners of Doobert. Chris is a technology guy in his “day” job and used his experience to create Doobe>[...]

The Airplane Was Spinning In A Nose-Down Attitude Before It Impacted Terrain On June 20, 2025, at 0900 eastern daylight time, a Pitts Aerobatics S-2B, N79AV, was destroyed when it >[...]

Also: United Elite Sues, Newark ATC Transitions, Discovery Moves?, Textron @ KOSH The Commemorative Air Force Airbase Arizona is taking its “Flying Legends of Victory Tour&rd>[...]

Classic Aero-TV: Up Close And Personal - The Aeroshell Aerobatic Team at Oshkosh

Classic Aero-TV: Up Close And Personal - The Aeroshell Aerobatic Team at Oshkosh ANN's Daily Aero-Term (07.13.25): Tactical Air Navigation (TACAN)

ANN's Daily Aero-Term (07.13.25): Tactical Air Navigation (TACAN) ANN's Daily Aero-Linx (07.13.25)

ANN's Daily Aero-Linx (07.13.25) NTSB Prelim: Pitts S2

NTSB Prelim: Pitts S2 Airborne 07.09.25: B-17 Sentimental Journey, Airport Scandal, NORAD Intercepts

Airborne 07.09.25: B-17 Sentimental Journey, Airport Scandal, NORAD Intercepts