Improper Lock-Washer Installation Could Lead To Servo

Malfunction

The FAA has issued an Emergency Airworthiness Directive (AD)

prompted by a report that a quality escape by a supplier has

occurred and certain hydraulic servo actuators (servo) may have a

loose nut, shaft, and clevis assembly due to improper lock-washer

installation. An investigation after an accident revealed the

clevis nut on the servo was loose. This condition, if not detected,

could lead to a malfunction of a servo in the flight control system

and subsequent loss of control of the helicopter.

The FAA has reviewed Bell Alert Service Bulletin (ASB) 407-11-96

and 427-11-35, both dated June 29, 2011, which specify the part

numbers and serial numbers of the affected servos and refer to ASB

407-05-70, Revision A, dated November 10, 2005; ASB 427-05-12,

Revision A, dated November 14, 2005; with HR Textron Service

Bulletin (SB) 41011300-67-01, Revision 2, dated November 9, 2005;

HR Textron SB 41011400-67-01, Revision 2, dated November 9, 2005;

and HR Textron SB 41011700-67-01, Revision 2, dated November 9,

2005. The ASBs also specify reidentifying the servos with a

“67-01” on the modification plate indicating the

inspection procedures were followed.

Transport Canada, the airworthiness authority for Canada,

notified the FAA that an unsafe condition may exist on these

helicopter models. Transport Canada advises that a quality escape

by a supplier has occurred, and a number of servos may have a loose

nut, shaft, and clevis assembly. Transport Canada states in its AD

that the loose connection is due to improper lock washer

installation, which is not traceable or identifiable except by

inspection. The authority also states a disconnect of the affected

parts may lead to loss of control of the helicopter. Transport

Canada classified the ASBs as mandatory and issued AD No.

CF-2011-17, dated June 30, 2011, to ensure the continued

airworthiness of these helicopters.

These helicopters have been approved by the aviation authority

of Canada and are approved for operation in the United States.

Pursuant to a bilateral agreement, Canada has notified the FAA of

the unsafe condition described in the AD. The FAA is issuing this

AD because it evaluated all information provided by Canada and

determined the unsafe condition exists and is likely to exist or

develop on other helicopters of these same type designs. Therefore,

this AD requires before further flight for certain affected servos

and within 25 hours time-in-service for certain other affected

servos, identified by a serial number, retracting the boot and

inspecting the servo as follows:

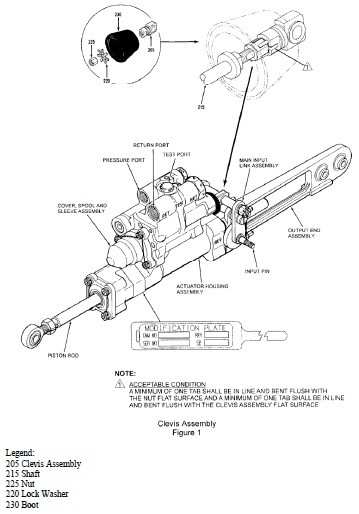

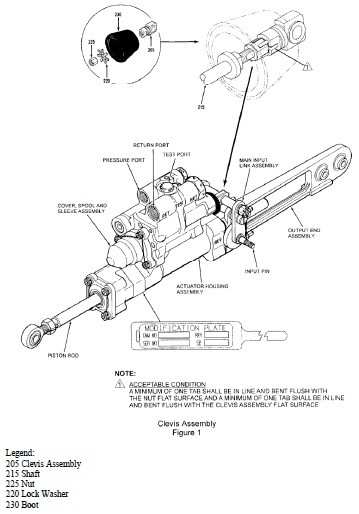

- Applying only hand pressure, determining whether the nut,

shaft, or clevis assembly turns independently. If the shaft turns

independently of the nut or the clevis assembly, before further

flight, replacing the servo with an airworthy servo.

- If the shaft does not turn independently, inspecting to

determine whether at least one tab of a lock washer is bent flush

against a flat surface of the nut and at least one tab of the lock

washer is bent flush against a flat surface of the clevis

assembly.

- If at least one lock washer tab is not aligned and bent flush

with a flat surface of the nut and at least one lock washer tab is

not aligned and bent flush with a flat surface of the clevis

assembly, before further flight, replacing the servo with an

airworthy servo.

- If any tab of the lock washer is not bent flush against either

a flat surface of the nut or clevis assembly, bending the tab flush

against a flat surface.

- Reidentifying the servo by metal-impression stamping or by

vibro etching “67.01” onto the modification plate.

- Before installing a servo with a P/N and S/N identified in this

AD, not identified by “67-01” on the modification

plate, inspecting it by following the requirements of this AD.

The actions must be done by following specified portions of the

alert service bulletins described previously.

This AD differs from Transport Canada AD in that the FAA does

not require that the servo be returned to the manufacturer. Also,

the FAA does not limit the applicability to specific

serial-numbered helicopters. The FAA has specified the inspection

requirements rather than referring to the applicable service

bulletins. The AD requires that the servo be replaced before

further flight, and the Transport Canada AD refers to the ASB,

which requires that the servo be replaced within 300 hours

time-in-service.

Aero-News: Quote of the Day (12.11.25)

Aero-News: Quote of the Day (12.11.25) ANN's Daily Aero-Term (12.11.25): Nonradar Arrival

ANN's Daily Aero-Term (12.11.25): Nonradar Arrival Classic Aero-TV: David Uhl and the Lofty Art of Aircraft Portraiture

Classic Aero-TV: David Uhl and the Lofty Art of Aircraft Portraiture Airborne-NextGen 12.09.25: Amazon Crash, China Rocket Accident, UAV Black Hawk

Airborne-NextGen 12.09.25: Amazon Crash, China Rocket Accident, UAV Black Hawk Airborne 12.05.25: Thunderbird Ejects, Lost Air india 737, Dynon Update

Airborne 12.05.25: Thunderbird Ejects, Lost Air india 737, Dynon Update