Fri, Jan 28, 2022

Manufacturer Tests Morphing Wing, Digital Controls, And Flat Antenna Under Green Initiative for Regional Commuters

Airbus completed the first test flight of its regional commuter, demonstration aircraft for the Clean Sky 2 program.

The company sent its C295, currently named “Flight Test Bed 2”, off from its final assembly point in Seville, Spain. With its maiden voyage out of the way, the C295 now begins evaluating its prototype features for future designs that could make them more environmentally friendly.

The Airbus C295 is a part of both the pan-European Clean Sky 2 and the EU Horizon 2020 research and innovation programs. Each of them, among other efforts around the world, hopes to increase efficiency and decrease harmful emissions of aircraft by using a slate of fresh technologies, refinements, and materials. The C295 tests some relatively affordable, production-ready features like a semi-morphing wing, a digital flight control system, and a low-profile satellite communications antenna. So far, it's expected that a standard, regional, multimission aircraft could see up to 43% CO2 and 70% NOx reductions can be achieved in a typical Search and Rescue mission of 400 nautical miles, as well as 45% less noise during take-off.

The aerodynamic design uses an evolution of dynamic winglets on the morphing wing. Similarly tailored, revised flight controls see improvements to all primary control surfaces for better, more efficient flight. Inside the aircraft, the flight control system has been digitized for electronic command and adjustment in-flight. Throughout the build process, the C295 has been built with updated materials, including liberal use of 3d-printed scalmalloy parts to simplify design and create pieces that would be impossible to manufacture through traditional means.

“The first flight of the C295 FTB2 is a key milestone that represents an important step forward in the program, following the successful integration of the new aero structures, power-on and ground tests. A few years ago this program was just a dream of a more sustainable future for aviation. Today we are at the final stage and we finally made it fly” said Francisco Javier Sánchez Segura, executive vice president engineering Airbus defence and space.

More News

Aero Linx: JAARS Nearly 1.5 billion people, using more than 5,500 languages, do not have a full Bible in their first language. Many of these people live in the most remote parts of>[...]

'Airplane Bounced Twice On The Grass Runway, Resulting In The Nose Wheel Separating From The Airplane...' Analysis: The pilot reported, “upon touchdown, the plane jumped back>[...]

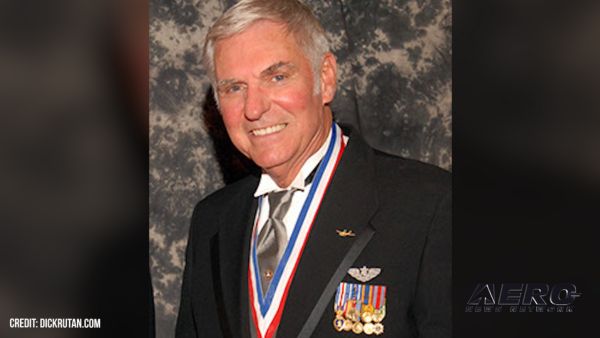

"Burt is best known to the public for his historic designs of SpaceShipOne, Voyager, and GlobalFlyer, but for EAA members and aviation aficionados, his unique concepts began more t>[...]

"Polaris Dawn, the first of the program’s three human spaceflight missions, is targeted to launch to orbit no earlier than summer 2024. During the five-day mission, the crew >[...]

There Are SO Many Ways To Get YOUR Aero-News! It’s been a while since we have reminded everyone about all the ways we offer your daily dose of aviation news on-the-go...so he>[...]

ANN's Daily Aero-Linx (05.04.24)

ANN's Daily Aero-Linx (05.04.24) NTSB Final Report: Quest Aircraft Co Inc Kodiak 100

NTSB Final Report: Quest Aircraft Co Inc Kodiak 100 Aero-News: Quote of the Day (05.04.24)

Aero-News: Quote of the Day (05.04.24) Aero-News: Quote of the Day (05.05.24)

Aero-News: Quote of the Day (05.05.24) Read/Watch/Listen... ANN Does It All

Read/Watch/Listen... ANN Does It All