Repeat After Us... It Could Have Been MUCH Worse

ANN Note:

Several of the pictures accompanying this article have been

"photoshopped" in order to make the damage more visible to our

readers, via extra contrast, sharpening or highlighting... this

process does not minimize the nature of the damage, but in fact may

tend to make the actual damage appear worse than it shows to the

naked eye. -- Jim Campbell, ANN

Editor-In-Chief

ANN Note:

Several of the pictures accompanying this article have been

"photoshopped" in order to make the damage more visible to our

readers, via extra contrast, sharpening or highlighting... this

process does not minimize the nature of the damage, but in fact may

tend to make the actual damage appear worse than it shows to the

naked eye. -- Jim Campbell, ANN

Editor-In-Chief

While the rumors have been running hot and heavy about the

damage suffered by over 60 aircraft at the Columbia Aircraft

factory in Bend, OR, an onsite inspection by ANN indicates that the

damage may be far less extensive than feared.

ANN had the opportunity to inspect dozens of aircraft that were

involved in the freak June 12th storm that dumped golf ball sized

hail on more than 60 aircraft that were being prepped for

delivery.

In an exclusive June 23rd ANN story on the

storm, Columbia Aircraft CEO Bing Lantis reported that

he missed the missed the storm, personally... since he was visiting

the Atlanta offices of Columbia's lead insurance provider, AIG.

"I was giving a presentation on what a safe risk we are," said

Lantis ruefully. "I'm told the hail came down suddenly... it was

not a hot day, not the kind of day you'd associate with a storm at

all."

Lantis adds workers only had time to pull one plane off the ramp

before the hailstones came... and once the hail came, it pelted the

ramp outside the factory for 12 minutes.

"Hailstones were hitting the runway and taxiway, and bouncing 10

feet in the air," Lantis says workers told him.

Lantis told ANN that the curved fuselages of the aircraft seemed

to have withstood the hail attack well... in fact, for the first

two days after the storm, it appeared there was no damage to the

planes at all.

Upon further inspection, however, Lantis said "you can see marks

where hailstones impacted the surfaces," when the light is right.

The marks appear in the plane's normally glossy paint, he says --

with no apparent damage to the composite skin.

ANN was given unrestricted access to the ramp where the damaged

aircraft awaited final inspection and repair, and walked through

the rows of aircraft, each of them featuring small black circles

(made by Columbia staff) indicating areas of hail impact revealed

by intensive inspection after Mother Nature had done her worst.

While the FAA and Columbia's insurers are working to come up

with a solution that not only makes sure that whatever damage that

may have been done is fixed, and gets these aircraft into the hands

of owners ASAP; the owners have apparently become just as concerned

about the delay in getting their aircraft as the damage from the

hail, as word reaches them that the structures are holding up well

to the scrutiny lavished upon them thus far.

Please note that ANN's inspection was admittedly cursory and not

performed by an A&P or other qualified aircraft technician

(though we have consulted with a number of qualified techs

about the issue), we had the chance to look over dozens of

aircraft, most of which were covered with countless small grease

pencil circles where inspectors indicated that hail had hit.

Our visual inspection, outside on a sunny afternoon revealed

that of over 2000 such circles -- inspected both directly and

obliquely (from an angle by which any potential depression was more

likely to be discerned), barely a dozen showed any actual

impact depression, cracking or other evidence of external

stigmata.

In hundreds of impacts inspected by ANN, under close

scrutiny and the use of magnifying lenses, areas circled by

Columbia's inspectors showed no visibly discernible evidence of

damage. Even attempts to feel for depressions or to "tap" the

structure to listen for evidence of a change in tone, a lack of

aural continuity, or other overt response revealed nothing we could

point to as out of the ordinary.

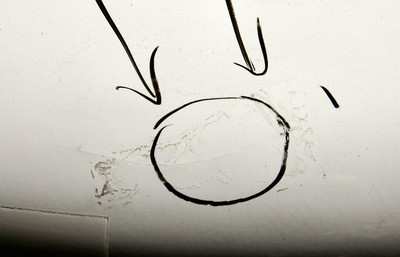

In those rare areas where cracking or paint penetration was

actually evident, the damaged area was taped over to prevent

moisture or other contamination from getting under the outside

paint layer and further exacerbating the potential for damage. From

what we have seen, Columbia's tech crews have done an amazing job

of not only inspecting each aircraft, but containing the potential

for further harm.

On several aircraft that were already being sanded/stripped of

paint and primer, close visual inspection of the structure and the

underlying composite material/fabric has revealed no breaks in the

actual composite materials -- and are (thus far) requiring little

more than refinishing (shown below, in process) to restore the

aircraft to flying status.

The most visible evidence of damage to the aircraft has

apparently occurred to the few metallic (and some plastic)

assemblies attached to the aircraft. In several cases, the metallic

housings surrounding the wingtip lights took hits that damaged the

aluminum shell, while several of the static wicks attached to the

trailing edges of the ailerons were hit and actually severed or

bent the insulated cables that comprise the internal portion of the

assembly.

A few of the protective lens covers that protect the landing

lights were also damaged.

In many cases, the lack of damage has made a difficult task all

that more rigorous. "Just because you can't see the damage is no

reason to take for granted that there is none... we're going over

every airplane very carefully," noted Columbia Aircraft's VP of

Customer Care, David McRae.

As an example of the kind of damage that Columbia staffers had

once feared would occur as the storm was underway, McRae showed ANN

several staff cars in the company parking lot, that had been hit by

the hail... some of which suffered thousands of dollars of damage

(and indeed, a local car dealer is reportedly having to total

millions of dollars of vehicles that were caught in the storm). In

comparison to a horribly pitted BMW, the Columbia birds looked like

they came off very well, indeed.

Columbia staffers are becoming more and more impressed, as the

inspections progress, of the ability of modern composite structures

to take the impacts of intense hail bombardment with little or no

permanent damage. Tests conducted with sample structures exposed to

impacts that were at least twice that of those estimated to have

occurred in the June 12th storm, have also shown no permanent

physical damage to the structures, and have further confirmed the

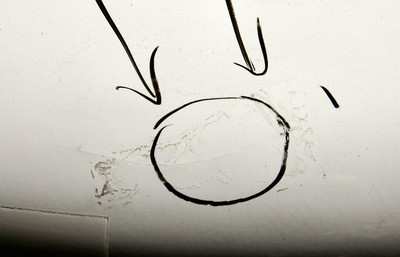

resilience of the current crop of composite aircraft designs. In

the coming weeks, Columbia's inspections, the FAA's judgement and

other engineering oversight is going to provide some amazing

information about the nature of composite structures (normal wing

Cross-section shown below) when exposed to such types of impact

damage.

ANN as been promised to be kept up to date of the progress made

by Columbia in bringing the damaged aircraft to a deliverable

condition (and indeed, Columbia has been more than forthcoming

about the matter as the information became known). Columbia CEO

Bing Lantis has been adamant about making sure that customers

picking up new aircraft be able to have complete confidence in the

birds, something that has been clouded by a rumor mill (often

associated with competitors unfortunately taking advantage of the

situation) that has greatly over-hyped the actual damage that was

done. In fact; as time goes on, Columbia is becoming more and more

impressed with what they are finding and the knowledge that they

are accumulating as a result.

"We have a unique situation," Lantis said, "because there's

never been a claim for hail damage on a Columbia -- and I would

guess that's probably pretty true of any other composite airplane.

It's a very durable material."

ANN will have more info on this story as it becomes

available.

Lockheed Hands Over Completed Artemis II Spacecraft

Lockheed Hands Over Completed Artemis II Spacecraft NTSB Final Report: Pulsar Super Pulsar

NTSB Final Report: Pulsar Super Pulsar Classic Aero-TV: Van Horn Rotor Blades -- Tail Rotor Replacements For Bell's 206

Classic Aero-TV: Van Horn Rotor Blades -- Tail Rotor Replacements For Bell's 206 ANN's Daily Aero-Term (05.02.25): Obstacle

ANN's Daily Aero-Term (05.02.25): Obstacle Aero-News: Quote of the Day (05.02.25)

Aero-News: Quote of the Day (05.02.25)