First Flight Of Prototype Expected In Germany This Summer

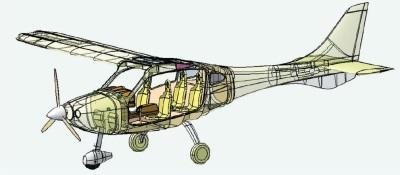

The Flight Design C4, the four-place GA aircraft currently in development by Flight Design has seen substantial progress this Spring, culminating in announcements during Sun ‘n Fun and Aero Friedrichshafen.

At Sun ‘n Fun Flight Design announced the Vision Touch Avionics suite at its annual press-conference with the complete system on display in the C4 interior mock up. The Vision Touch suite is based around the Garmin G3X Touch system as PFD and MFD (Primary and Multifunction Displays).

The G3X Touch is a new product offering from Garmin that features both advanced synthetic vision capabilities and a choice of touch screen and conventional button/knob input as well. The inclusion of this system will give C4 owners the greater situational awareness afforded by synthetic vision and the simplicity of operation through the advanced touch screen displays.

Other components include the Garmin GNC 255 Nav-Com as a secondary navigation system and back up radio, the Garmin GMA 350 audio panel and the Garmin GMC 305 autopilot. To top off this impressive list are centrally located RC Allen solid-state digital Directional Gyro, Attitude indicator, full-size airspeed and altimeter.

The Vision Touch avionics suite uses a combination of TSO’d and non-TSO’d components. The certification plan of the Vision Touch installation follows the precedence EASA had established with certification of our CTLS at end of 2013. The use of this system requires analysis of the airframe level architecture in a different way in the certification process than for a TSO qualified system.

The system will make use of two completely independent air data sources for all functions: Total pressure, static pressure, angle of attack sensing along with separate redundant electrical busses. The resulting additional redundancy can be of a higher level than for a simple TSO qualified system. When flying at night or in IMC, additional precautions have to be provided. This is achieved by adding standard TSO approved instrumentation as a backup. To ensure that the TSO qualified information is available for the pilot, these instruments are located in plain sight and high up on the panel. This is the reason for the arrangement having the backup analogs in the center stack right on top. The careful choice of avionics allows for a significantly lower price point and much higher flexibility for future system enhancements and upgrades. With this selection of a major cost driver for an aircraft of this class, Flight Design has taken another major step to confirm the anticipated price tag of the C4.

An update from Michael Gifford of Continental Motors at Aero Friedrichshafen was that the IO-360AF 180 HP Alternate-Fuels capable engine is progressing towards FAA Part 33 certification, which is expected in August 2014. The IO-360AF will be one of the standard versions available under the engine’s FAA type certificate. “We are very pleased with the cooperation we have gotten from Continental Motors on the C4 project,” said Flight Design President Matthias Betsch. They have been proactive in the C4 design process and we look forward to expanding our cooperation for the Diesel powered version of the C4 in the future.”

Another interesting development involving the C4 is the advanced occupant protection research and testing using the C4 as the first example. This program is called the “Safety Box”.

The Safety Box program made its public debut at the Aero Friedrichshafen convention held in April. The German Ministry of Economic Affairs granted funding for a research project that aims at development of a modular “Safety Box” cabin safety system for light aircraft. The new system will provide a safety cage around the occupants of an aircraft, whose functionality builds upon several concepts, namely intelligently designed and located crash absorbing components, a stiff cabin structure with dedicated load paths for the majority of crash scenarios, advanced seat installation and restraint systems. This is significantly supported by optimized cabin ergonomic designs and enhanced fire protection concepts.

Final assembly of the C4 Proof of Concept flight test prototype is underway with the airplane's first flight expected to happen this summer in Kamenz Germany. Flight Design made the decision early on to build more than one airframe for the proof of concept stage of development. This allows a higher level of structural testing of the design without the potential of damaging the flight test airframe. The proof of concept prototype will undergo numerous ground tests including ground vibration testing (GVT) from an independent consultant engineering firm. Flight testing of the C4 will be performed by an FAA approved Swiss test pilot, Damian Hischier, a graduate of the National Test Pilot School (NTPS) located at Mojave, CA.

Design work continues with the staff of Flight Design engineers to complete the design of the

conforming C4 with the expectation to achieve certification early in 2015. A conforming model of an aircraft is one that is used to show compliance to EASA or the FAA. Work on production specification molds has started and expert consultants from Germany and the USA have been participating in the design review process to optimize the C4 design for performance, stability and control.

Flight Design Americas will build a final assembly facility for the C4 at Newport, Vermont. Plans include a new 50,000 square foot assembly hall along with many new facilities. Newport Vermont is within an economic development zone created by the State of Vermont to foster such new ventures and is well known for its proximity to the Jay Peak resort nearby. The Newport Airport is also the location for an onsite U.S. Customs and bonded warehouse facility which will greatly aid in timely importation of container shipments from the nearby port of Montreal. C4 aircraft assembled in Newport will be delivered to customers in North and South America.

(Images provided by Flight Design)

ANN's Daily Aero-Term (04.25.24): Airport Rotating Beacon

ANN's Daily Aero-Term (04.25.24): Airport Rotating Beacon ANN's Daily Aero-Linx (04.25.24)

ANN's Daily Aero-Linx (04.25.24) Klyde Morris (04.22.24)

Klyde Morris (04.22.24) Airborne 04.24.24: INTEGRAL E, Elixir USA, M700 RVSM

Airborne 04.24.24: INTEGRAL E, Elixir USA, M700 RVSM Airborne 04.22.24: Rotor X Worsens, Airport Fees 4 FNB?, USMC Drone Pilot

Airborne 04.22.24: Rotor X Worsens, Airport Fees 4 FNB?, USMC Drone Pilot