Cracking Discovered In Weld Joints In Tail Post

The FAA has issued a Special Airworthiness Information Bulletin (SAIB) for owners and operators of certain Piper Aircraft, Inc. Model PA-18 (L-21) airplanes. The agency has been alerted to cracking discovered in the weld joint of the aft fuselage tail post of an airplane operated outside the U.S. This SAIB also provides guidance on recommended inspections for various Piper airplane models with similar tail post configurations.

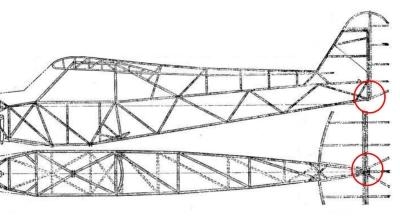

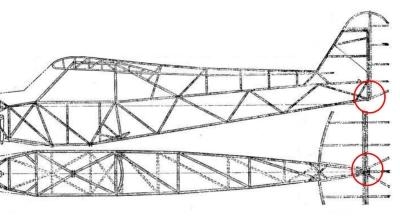

The FAA recently received notice of this issue from a foreign operator. A Piper Model L-21B (PA18-135) airplane fuselage was completely disassembled to replace the worn fabric fuselage covering. After removing the fabric covering, paint was removed from the fuselage frame in areas considered susceptible to high stress and at major weld joints. A fluorescent penetrant inspection (FPI) was done on all these areas. The FPI inspection revealed two cracks in the fuselage tail section protruding into the lower rudder attachment hinge area (see Figure 1). To determine the extent of cracks into the adjacent welds and tubing, additional x-ray inspection of the area was done. The x-ray inspection revealed that the cracks did protrude into the adjacent weld areas.

Additional airplanes from the operator were inspected and a total of three out of five airplanes showed cracking at the same location. The lowest time airplane with cracking had accumulated approximately 4,000 hours total time-in-service (TIS). The highest time airplane without cracking had accumulated over 6,500 hours TIS. The x-ray inspections were also used to check for corrosion of the tubes and welds that could contribute to the problem. Only minor internal corrosion was visible on any of the inspected airplanes.

There have been no reports of such damage within the Service Difficulty Report (SDR) or Malfunction/Defect Report (MDR) systems. Some operators have informally provided experience suggesting similar damage may have occurred on other Piper Cub series airplanes, especially when operated on rough terrain. To this point, all damage has been discovered during maintenance.

If undetected, these conditions could eventually lead to significant cracking and / or corrosion of the fuselage tube structure and result in a potential safety of flight hazard such as loss of control of the lower rudder hinge or tail wheel.

The FAA recommends the Piper airplane models listed below that have accumulated 1,000 hours total TIS be inspected within the next 100 hours TIS in the fuselage tail post area. We recommend use of an inspection method such as fluorescent penetrant and / or x-ray. Additionally, we recommend repeating the inspection every 1,000 hours TIS. These inspections are particularly important if the aircraft is subject to operation in severe turbulence, towing, or on rough terrain.

The focus is on airplane model variants with tube and fabric construction with tailwheel and rudder hinge support structures converging at the tail post joint construction.

Depending on the aircraft configuration, the area may be difficult to inspect due to limited accessibility with the fabric installed. We recommend that you inspect with the fabric removed. There may also be alterations available that provide increased accessibility to the area. The FAA recommends that damaged components be repaired or replaced if cracking or corrosion is found.

Affected models include: AE-1, E-2, F-2, HE-1, J2 series, J3C series, J3F series, J3L series, J4 series, J5 series, L-4 series (Army), L-14, L-18C (Army), L-21 series (Army), NE-1 and NE-2 (Navy), PA-11 series, PA-12 series, PA-14, PA-15, PA-16 series, PA-17, PA-18 series, PA-19 series, PA-20 series, PA- 22 series, PA-25 series, TG-8, and XLNP-1.

(Upper image provided by the FAA. PA-18 image from file.)

Airbus Racer Helicopter Demonstrator First Flight Part of Clean Sky 2 Initiative

Airbus Racer Helicopter Demonstrator First Flight Part of Clean Sky 2 Initiative Diamond's Electric DA40 Finds Fans at Dübendorf

Diamond's Electric DA40 Finds Fans at Dübendorf ANN's Daily Aero-Term (04.23.24): Line Up And Wait (LUAW)

ANN's Daily Aero-Term (04.23.24): Line Up And Wait (LUAW) NTSB Final Report: Extra Flugzeugbau GMBH EA300/L

NTSB Final Report: Extra Flugzeugbau GMBH EA300/L Classic Aero-TV: 'Never Give Up' - Advice From Two of FedEx's Female Captains

Classic Aero-TV: 'Never Give Up' - Advice From Two of FedEx's Female Captains