Four Common Issues Now Repairable

While a new repair program won't cover all ills, a major issue for Bonanza owners is in the process of being resolved. For the longest time, damage/cracks occurring to a Bonanza 'V-Tail' Ruddervator meant a horrific search for parts or salvaged assemblies -- which are in VERY short supply -- to get the bird back in the air.

And sometimes, it just didn't happen. Long out of production, and with little help available from Textron (currently the Father company for the Beech Bonanza legacy), Ruddervator repair can become a huge hassle.

SRS Aviation has taken a big step forward in dealing with the issue (and there may be others on the way). Already well-known for offering parts and support solutions for a whole flock of airplanes, SRS' Dave Lauren told ANN that he now has SOME repair authority to deal with some of the most common problems that may afflict the V-Tail Beech breed.

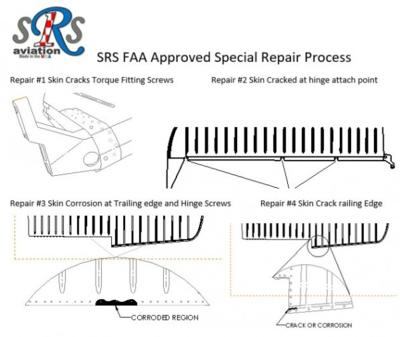

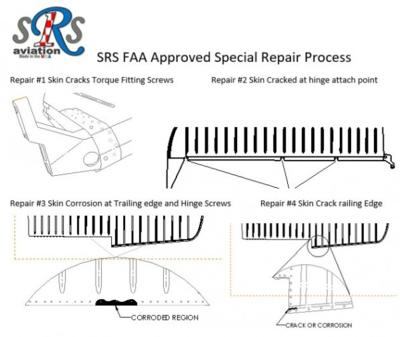

Currently, he can fix four troublesome issues:

- Skin cracks emanating from the three torque fitting holes.

- Skin cracks emanating from hinge area (typically caused from tooling damage)

- Skin corrosion at the trailing edge and around three hinge screws

- Skin trailing edge crack

The repair program is shop-specific to SRS... meaning that, "this is a FAA-approved Special Repair Process that is attached to our SRS FAA-Approved Repair Station certificate." Lauren says that typical repair costs average about $1600... "However, if we have to do a combination of repairs or must replace magnesium torque fittings there are additional costs."

Mind you, not all ruddervators can be repaired... "in cases where the crack is five inches long and/or there are holes in the Ruddervator from corrosion, the Ruddervator would not be repairable."

If you have questions about the suitability of your control surfaces for repair, Lauren invites you to email or text photos of the damage to SRS (dave@srsaviation.com).

In the case of stripping and treating an assembly, SRS notes that, "we have teamed up with Wipaire in St Paul, Minnesota, which has a full paint facility. I don't speak for them, but typically they charge $600 to strip and evaluate a control surface. This gets paid whether your Ruddervator passes or fails. If it passes, the typical full cost is $1400 for strip and paint, in addition to the repair costs." However; if the surface is free of corrosion, SRS can both perform repairs and paint them, as well in their shop -- a program that typically 'does hundreds' of controls a year.

Of particular interest, Lauren mentioned their ability to convert ruddervators from one configuration another... since there are several potential types involved. He explained that there were three different styles of ruddervators throughout the years of V-Tail production:

- 1947-1956: Square tip counterbalance weight with narrow chord and no center spar

- 1957-1963: Square tip counterbalance weight ruddervators with a center spar

- 1964-1982: Pointy tip counterbalance weight with center spars

The reason this comes up, is the fact that SRS also has the ability to convert SOME of them from one type to another... particularly valuable if you come across a needed/serviceable Ruddervator that doesn't otherwise fit your airframe. SRS can convert 1957-1963 ruddervators to late model 1964-1984 style (and vice versa) by swapping out the weight covers and some structural parts. Typical cost is $1600. Unfortunately, they cannot do anything with the 1947-1956 Ruddervator because they have a different trim tab hinge with a narrow chord.

More info to come...

ANN's Daily Aero-Term (04.24.24): Runway Lead-in Light System

ANN's Daily Aero-Term (04.24.24): Runway Lead-in Light System ANN's Daily Aero-Linx (04.24.24)

ANN's Daily Aero-Linx (04.24.24) Aero-FAQ: Dave Juwel's Aviation Marketing Stories -- ITBOA BNITBOB

Aero-FAQ: Dave Juwel's Aviation Marketing Stories -- ITBOA BNITBOB Classic Aero-TV: Best Seat in The House -- 'Inside' The AeroShell Aerobatic Team

Classic Aero-TV: Best Seat in The House -- 'Inside' The AeroShell Aerobatic Team Airborne Affordable Flyers 04.18.24: CarbonCub UL, Fisher, Affordable Flyer Expo

Airborne Affordable Flyers 04.18.24: CarbonCub UL, Fisher, Affordable Flyer Expo