Looking To The Past To Recreate The Future

The Goodyear Tire & Rubber Company and NASA recently took a

small step backward, in order to make one giant leap forward and

help prepare for future missions to the moon and to Mars.

Goodyear and the NASA Glenn Research Center recently completed a

jointly-funded project for the development and production of 12

replicates of the original wire-mesh moon tire used on the Apollo

Lunar Roving Vehicle in the early 1970s. This was the first step

toward understanding this unique non-pneumatic tire technology, and

its applications on both the moon and Earth.

"Although there was some reference material for designing the

replicate tire, there was little detail about the manufacturing

process," said Goodyear Project Leader Rick Laske, noting how the

team had to reinvent techniques to recreate the wire mesh tire.

The team examined one of the moon tires on display at the

National Air and Space Museum in Washington, DC and corresponded

with two retired members of the Apollo Lunar Roving Vehicle team,

who each had a tire that had been given to them as a souvenir for

their work. Examination of the original moon tires provided the

primary reference information for judging the quality of the

replicates, according to Vivake Asnani, NASA's principal

investigator.

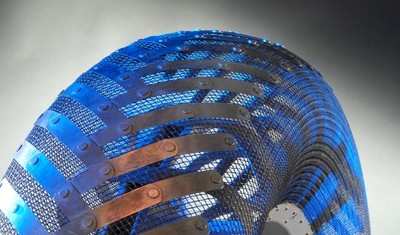

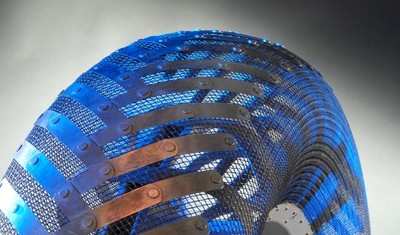

Four major components comprise the tire and wheel design: mesh,

tread, inner-frame, and hub. The mesh is woven from piano wire and

the tread is a series of metal strips intended to protect the mesh

from impact while providing increased contact area for floatation

in soft soil. An inner-frame, comprised of a relatively rigid metal

structure, prevents the mesh from over- deforming during impact,

while the hub holds the mesh and inner-frame together and connects

the assembly to the vehicle.

"Before the wire mesh could be woven, 3,000 feet of wire had to

be custom- crimped and cut into 800 pieces," said Laske. A hand

loom was designed to weave the crimped wires into a rectangle

measuring approximately 100 inches long and 25 inches wide. Each

end of the rectangular weave was then interlaced by hand to form a

cylinder, which behaves in a manner similar to a child's finger

trap puzzle, lengthening and shortening with changes in its

diameter.

Sides of the mesh cylinder were pulled down and clamped to a

circular jig, roughly the size of a wheel hub, to give the mesh the

shape of a tire. Then the jig and mesh were baked in an industrial

oven to relieve residual stress from the wire.

The 12 replicate tires were evaluated for geometry, stiffness,

and other performance factors, and compared against data from the

two antique moon tires, as well as limited measurements taken in

the 1960s. "The measurements indicate that the original and

replicate wire mesh moon tires have nearly identical mechanical

properties," said Asnani, "We are now testing the replicates to

determine their traction and endurance capabilities. These data

will enable NASA and industry to determine possible applications

for the wire mesh tire."

Goodyear isn't the only company hoping to get a piece of moon

pie.

As ANN reported, Michelin is also working on a

prototype lunar tire.

Aero-TV: DeltaHawks Diesel Power Steps Into the Spotlight

Aero-TV: DeltaHawks Diesel Power Steps Into the Spotlight NTSB Prelim: Mooney Aircraft Corp. M20K

NTSB Prelim: Mooney Aircraft Corp. M20K ANN FAQ: Turn On Post Notifications

ANN FAQ: Turn On Post Notifications ANN's Daily Aero-Linx (12.20.25)

ANN's Daily Aero-Linx (12.20.25) Aero-News: Quote of the Day (12.20.25)

Aero-News: Quote of the Day (12.20.25)