Change Is Coming

By Jerry Gregoire

Until recently, the role of the flight simulator has been, almost exclusively, as stand-in for the airplane. This is, in large part, because governmental agencies have assumed the role of chief designer by establishing the requirements for certification and then interpreting those requirements as certifier of the devices. The adaptation and adoption of more useful and cost effective solutions has been brought nearly to a standstill by the rulemaker’s inability keep up with advances in the technology. In this one dimensional universe, value is measured and certifications awarded based solely on fidelity, the simulator’s ability to closely mimic the cockpit’s appearance and aircraft’s performance characteristics.

Whether by accident or by design, when the FAA issued its rules for certifying Basic Aviation Training Devices (BATD) and Advanced Aviation Training Devices (AATD) in 2008, they opened the door for new generations of simulators by allowing the addition of enhancing technologies without the risk of having the simulator lose its certification. Examples of these enhancing technologies include lower cost motion platforms added to traditionally static simulators, an autonomous, full function ATC presence resident on the simulation engine for communications training, and the integration of gaming technology.

This has created a second dimension of value for flight training providers which, for the sake of this discussion, can best be described as "generations" where training tasks formally delivered separately via partial task trainers or human instructors is now an integral part of a "live" simulation. At its most macroscopic, there are four primary generations, they are: the simulation device as stand-in for aircraft, the device as content and skills delivery platform, device delivering flight experience based on individual need and, finally, device as portable mentor.

Generation 2 simulators are already in the marketplace from some manufacturers. These content and skills delivery systems include, among other things, A.I. ATC communications trainers, IOS device GPS spoofing, and preloaded scenario-based training with analysis and scoring. Newly development Generation 3 simulators integrate the best of “gaming” based experiential training technology with highly developed measuring and scoring schemes and “context engines” for voice recognition and response to make two-way interaction and coaching delivered by the simulator possible.

The capabilities of Generation 4 simulators are best described as the simulator as mentor. This builds on the work of previous generations to create a portable, vehicle independent, training solution that can move from simulation vehicle for training to aircraft.

The challenge for companies developing these enhanced simulators for the marketplace will not be in the engineering, it will be bringing the regulatory authorities and the training providers along for the ride.

Aviation Myth #463: Costs Reflect Value

In 2006, a fellow pilot and I had just finished a check ride in a Level D King Air simulator, a machine that cost well in excess of seven million dollars. We experienced some difficulty flying a circle-to-land approach because the exterior visuals were so poor. They were hazy, uneven in intensity and color and lacked detail. As we climbed out of what was a very frustrating session, we began a discussion about the state of the technology and after some very preliminary work, realized that given the state of technology, we could easily design and deliver a visual system that was far better than this one at a tiny fraction of the cost. Which begs the question, if we knew how to do it why weren't the manufacturers of these systems doing it? High end simulators is a lucrative but highly competitive business with at least a dozen companies vying for orders in a market that, generally, consumes less than one hundred units per year. One would think that exploiting opportunities for competitive advantage would

be foremost on their minds. Regrettably, the answer has to do with the momentum that keeps companies and regulatory agencies stuck in old paradigms combined with a fundamental misunderstanding of the marketplace and its needs.

In spite of their expense, impressive size and level of complexity, the industry is coming to realize that flight simulators, as specified by the FAA and their counterparts around the world, are blunt instruments. The manufacturers seem insensitive to the demands of an increasingly price sensitive market, building solutions that are wholly inappropriate to the needs of flight training providers, particularly those catering to the primary (ab initio) market. Those companies that only manufacture simulator hardware for a living will surely disappear, some very soon. What is missing in the current designs is the true and certain future role of the simulator, not just as a training aid but as a training delivery transport device.

As we begin the process of developing new roles and capabilities for the simulator, primary training seems the most likely place to begin. Besides being the lessor regulated end of the training rainbow, it is the most cost sensitive and the area most likely to benefit from the integration of features and capabilities that may not be considered as valuable to the 25,000 hour pilot.

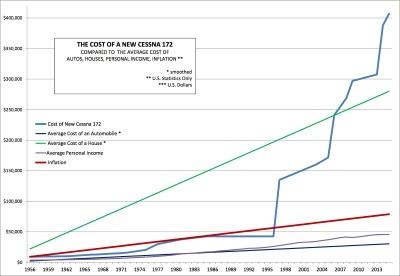

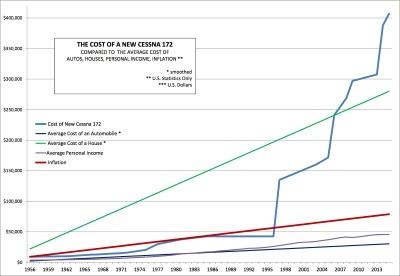

Hastening the need for more effective and cost efficient solutions for primary training is the phenomenon we see in capital equipment costs. There are few manufactured products that one can think of that have not improved in their value proposition over time. Meaning, there are few machines that, over time, have not gotten significantly less expensive, like computers, or have delivered more features and capability for the same, inflation adjusted, price, like automobiles.

It is completely accurate to say that anything to do with designing, building or supporting aircraft is the most hidebound, wasteful process in manufacturing of any kind. To date, this sloppiness has been not been a problem for manufacturers to resolve. Instead they have just simply passed their problems on to their customers in the form of higher prices. Aviation manufacturers have been operating in silos, ignoring the fundamentals of manufacturing, logistics and cooperative design that have been the standard in other industries for decades. Up to this point, aircraft and component manufacturers have operated on the absurd assumption that a growth strategy based solely raising prices every year could be sustained indefinitely.

In 1956 a new Cessna 172 cost about $9,000, which would be $79,000 in today’s dollars. In 2014, a new Cessna 172 actually costs a heart stopping $407,000.00. Cessna has had fifty years to figure out how to apply the fundamentals of automation to the manufacture of this airplane and yet they still build them like they’re not quite sure how they go together. As value propositions go, it doesn’t get much worse than this. Cessna can operate this way because, while they may have competition, no one is doing it any better. Among the short list of battle tested, widely available, easily supportable, VFR/IFR flight training platforms, the Piper Archer, a Diamond DA40, and the Cirrus SR20 all sell for around $400,000.

The price of new training aircraft disconnected itself from reality with the arrival of the General Aviation Revitalization Act of 1994. Excuses number in the hundreds.

Light Sport Aircraft, which were supposed to provide a solution by delivering platforms for around $150,000, mostly failed in the US training market because of a lack of durability and, in some cases a weird and unexpected shortcoming, such as the aircraft’s inability to effectively heat the cabin.

In Part 2, why an airplane makes a terrible classroom.

(Images provided by the Author)

(Jerry Gregoire is the founder and owner of Redbird Flight Simulations)

ANN's Daily Aero-Term (04.20.24): Light Gun

ANN's Daily Aero-Term (04.20.24): Light Gun Aero-News: Quote of the Day (04.20.24)

Aero-News: Quote of the Day (04.20.24) ANN's Daily Aero-Linx (04.21.24)

ANN's Daily Aero-Linx (04.21.24) Aero-News: Quote of the Day (04.21.24)

Aero-News: Quote of the Day (04.21.24) ANN's Daily Aero-Term (04.21.24): Aircraft Conflict

ANN's Daily Aero-Term (04.21.24): Aircraft Conflict