Raburn Calls Growing Pains "Disappointing" -- And Swears

Company Will Prevail

(Editor's Note -- Below is the complete

text of an advisory letter sent Friday to customers of Eclipse

Aviation, from company CEO Vern Raburn (shown below, right),

detailing the reasons for a regretable slip in the company's

planned production schedule through 2007 -- and the steps Eclipse

is taking to resolve those issues.)

It is natural for a new airplane company to experience growing

pains as it transitions from development to a predictable

production rate. However, our journey has introduced far more

challenges than we anticipated. As a result, the 2007 Eclipse 500

production schedule has slipped. This is very disappointing to us,

as I know it is to you.

Our sole focus is on delivering a safe, reliable,

high-performance aircraft to you in the most expedient manner

possible.

While there are challenges, which I

have outlined below, we have taken aggressive action to eliminate

the problems and are making excellent progress. The purpose of this

letter is to fill you in on the specific obstacles we have

encountered, and let you know what we are doing to remove them.

While there are challenges, which I

have outlined below, we have taken aggressive action to eliminate

the problems and are making excellent progress. The purpose of this

letter is to fill you in on the specific obstacles we have

encountered, and let you know what we are doing to remove them.

At a high level, our production issues relate to the

manufacturing process, and are not founded in Eclipse 500 design

flaws. At their core, these are issues with internal processes and

staffing, although parts shortages and quality problems have

absolutely contributed to the delay.

Following is a detailed summary of the issues, and the actions

we have taken to resolve them.

Summary of Production Issues & Corrective Action

Functional Test Procedures

- ISSUE: The initial Functional Test Procedures documentation

used to verify the accurate function of airplane systems was not

sufficient.

- RESOLUTION: These documents have been completely re-written and

approved by the FAA. They will be re-written once again to

eliminate system testing duplication, which will dramatically

reduce manufacturing cycle time.

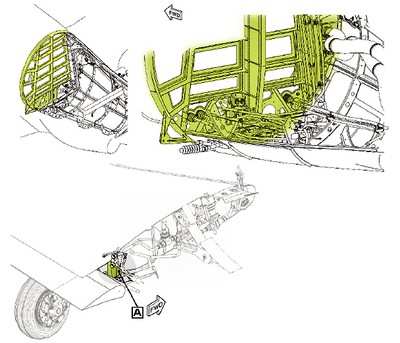

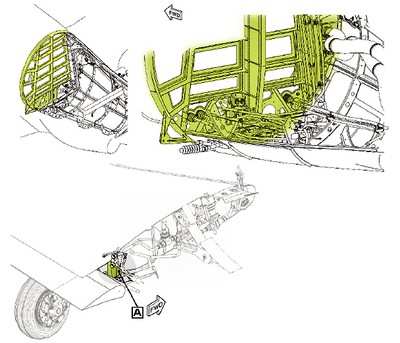

Aft Wing Attach Fitting

- ISSUE: A loose bushing was found inside the rear wing attach

point.

- RESOLUTION: The design has been corrected to ensure stable

bushing placement, and early aircraft have been

reworked.

Manufacturing Workforce

- ISSUE: Although we have been hiring many talented people in all

areas of the company, we are still short staffed in

manufacturing.

- RESOLUTION: We have been aggressively hiring contract workers,

most of whom want to become full-time employees. Tomorrow we will

make an exciting announcement introducing our new vice president of

manufacturing, who brings us extensive high-volume manufacturing

expertise.

Parts Shortages

- ISSUE: A number of suppliers experienced parts shortages as we

kicked off production in 2006.

- RESOLUTION: When original suppliers fell short, we moved

quickly to find new component sources. Although our new suppliers

had some start-up delays, these issues are now behind us.

Supplier Quality

- ISSUE: Two suppliers have experienced significant quality

issues that have caused production line rework and delays.

- RESOLUTION: Both of these suppliers are working through the

root cause of these issues and taking corrective action. We have

worked extensively with the suppliers and seen improvements.

Structural Requirements

- ISSUE: Friction Stir Weld and thin skin construction of the

Eclipse 500 fuselage requires different handling, assembly and

repair than conventional structures. Every situation requires

engineering analysis and DER approval.

- RESOLUTION: We now have a deeper understanding of these

structural requirements, and have developed a standard repair

document that is significantly reducing the amount of time it takes

to disposition manufacturing errors.

Component Failure Rates

- ISSUE: We are seeing a higher failure rate on some components

than anticipated.

- RESOLUTION: We have been evaluating the root cause of the

failures and are making progress to quickly resolve the issues, but

in the short term we have an adequate replacement stock for all of

these components.

Production Rate

- ISSUE: Achieving our target production rates requires

innovation within every facet of the traditional aircraft

manufacturing process.

- RESOLUTION: We are employing four strategies to achieve

high-rate production, which are: 1) bring in experienced automotive

production leaders; 2) build-in-position through quality inspection

buy-off; 3) leverage robotics in primary assembly to eliminate

human error and reduce cycle time; and 4) conduct automated system

testing early in the build process.

I would like to offer my overriding view of this situation. We

have had a series of unrelated problems ranging from supplier

delays, to design glitches, to leadership oversights that have

created something of a perfect storm in terms the start up of the

production line. Collectively, these issues have significantly

impacted our schedule, and challenged us more than ever before.

Of course, our critics are eager to triumphantly say "I told you

so!" And perhaps they are right -- for the near term. I have often

told you that although Eclipse is not yet as good I believe we will

eventually be at avoiding problems, I’ll put our ability to

solve tough problems up against that of any other individual or

company. Pundits have predicted our demise an almost incalculable

number of times. Even in extreme situations such as the Williams

International engine failure, we have prevailed. There is zero

doubt in my mind that our current challenges will produce a

stronger company, and a better product. We’ve done it before,

and we will do it again.

One overarching commitment we have not, and will not, waver from

is to provide you with the very best and the very safest aircraft

possible. Although the delay in deliveries is very frustrating to

you (and to the entire team at Eclipse), I simply will not allow

anything to compromise the quality of this jet or the safety of our

customers.

Our focus now is on catching up, and proving to the FAA that we

are ready to take the next step. While it is impossible to predict

the exact timing for the receipt of our Production Certificate

(PC), we will keep you informed of our progress. It is very

important to note that we are working a parallel path with the FAA

to produce aircraft under the type certificate while simultaneously

working toward PC. Prior to receiving PC, we can and will continue

to deliver aircraft by working with the FAA to issue Eclipse 500

Certificate of Airworthiness.

As issues arise, we will continue to move as swiftly as possible

to drive to solutions that serve your best interests. In the past,

I have been unwilling to discuss problems until I could also

provide you with solutions. While we will always strive for this

ideal communication, I have come to realize that there simply will

not always be an immediate resolution to every issue. Thus, I

intend to share updates with you as often as possible, whether they

highlight our successes or our challenges.

As always, I thank you for your patience, encouragement and

belief in Eclipse.

ANN's Daily Aero-Linx (04.16.24)

ANN's Daily Aero-Linx (04.16.24) Aero-News: Quote of the Day (04.16.24)

Aero-News: Quote of the Day (04.16.24) Airborne 04.10.24: SnF24!, A50 Heritage Reveal, HeliCycle!, Montaer MC-01

Airborne 04.10.24: SnF24!, A50 Heritage Reveal, HeliCycle!, Montaer MC-01 Airborne 04.12.24: SnF24!, G100UL Is Here, Holy Micro, Plane Tags

Airborne 04.12.24: SnF24!, G100UL Is Here, Holy Micro, Plane Tags Airborne-Flight Training 04.17.24: Feds Need Controllers, Spirit Delay, Redbird

Airborne-Flight Training 04.17.24: Feds Need Controllers, Spirit Delay, Redbird